Ultrasonic sensors are sensors that convert ultrasonic signals into other energy signals (usually electrical signals). Ultrasonic waves are mechanical waves with vibration frequencies higher than 20kHz. It has the characteristics of high frequency, short wavelength, small diffraction phenomenon, especially good directionality, and the ability to propagate directionally as rays. Ultrasonic waves have a great ability to penetrate liquids and solids, especially in solids that are opaque to sunlight. Ultrasonic waves will produce significant reflections when encountering impurities or interfaces, forming reflected echoes, and can produce Doppler effects when encountering moving objects. Ultrasonic sensors are widely used in industry, national defense, biomedical and other fields.

component

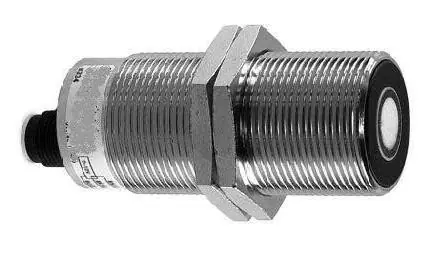

The commonly used ultrasonic sensors are composed of piezoelectric chips, which can emit and receive ultrasonic waves. Low power ultrasound probes are commonly used for detection purposes. It has many different structures, including straight probe (longitudinal wave), oblique probe (transverse wave), surface wave probe (surface wave), Lamb wave probe (Lamb wave), dual probe (one probe emitting and one probe receiving), etc.

performance index

The core of an ultrasound probe is a piezoelectric chip inside its plastic or metal casing. There can be many types of materials that make up a chip. The size of the chip, such as diameter and thickness, also varies, so the performance of each probe is different. We must understand its performance in advance before using it. The main performance indicators of ultrasonic sensors include:

working frequency

The working frequency is the resonance frequency of the piezoelectric chip. When the frequency of the AC voltage applied to both ends is equal to the resonant frequency of the chip, the output energy is maximized and the sensitivity is also highest.

sensitivity

It mainly depends on the manufacturing of the chip itself. High electromechanical coupling coefficient and sensitivity; On the contrary, the sensitivity is low.

Directionality

Range of ultrasonic sensor detection

Main applications

Ultrasonic sensing technology is applied in different aspects of production practice, and medical applications are one of its main applications. The following uses medicine as an example to illustrate the application of ultrasonic sensing technology. The application of ultrasound in medicine is mainly for diagnosing diseases, and it has become an indispensable diagnostic method in clinical medicine. The advantages of ultrasound diagnosis are: no pain or damage to the subject, simple method, clear imaging, and high diagnostic accuracy. Therefore, promotion is easy and welcomed by healthcare workers and patients. Ultrasound diagnosis can be based on different medical principles, and let's take a look at a representative type A method. This method utilizes the reflection of ultrasonic waves. When ultrasound propagates through human tissue and encounters two media interfaces with different acoustic impedances, reflection echoes are generated at that interface. When encountering a reflecting surface, the echo is displayed on the oscilloscope screen, and the impedance difference between the two interfaces also determines the amplitude of the echo.

In the industrial field, the typical applications of ultrasound are non-destructive testing of metals and ultrasonic thickness measurement. In the past, many technologies were hindered by the inability to detect the interior of object tissues, and the emergence of ultrasonic sensing technology has changed this situation. Of course, more ultrasonic sensors are fixedly installed on different devices, silently detecting the signals that people need. In future applications, ultrasound will be combined with information technology and new material technology, resulting in more intelligent and high-sensitivity ultrasound sensors.

Application of Ultrasonic Distance Sensor Technology

Ultrasonic waves have a great ability to penetrate liquids and solids, especially in opaque solids, where they can penetrate depths of several tens of meters.

Ultrasonic waves will produce significant reflections when encountering impurities or interfaces, forming echoes, and can produce Doppler effects when encountering moving objects. Therefore, ultrasonic testing is widely used in industry, national defense, biomedical and other fields.

Ultrasonic distance sensors can be widely used in areas such as level monitoring, robot collision prevention, various ultrasonic proximity switches, and anti-theft alarms. They are reliable, easy to install, waterproof, have a small emission angle, high sensitivity, and are convenient to connect with industrial display instruments. They also provide probes with larger emission angles.

Specific applications

1、 Ultrasonic sensors can detect the status of containers. Installing an ultrasonic sensor on the top of a plastic melt tank or plastic pellet chamber and emitting sound waves into the interior of the container can be used to analyze the container's status, such as full, empty, or half full.

2、 Ultrasonic sensors can be used to detect transparent objects, liquids, any rough, smooth, light dense materials, and irregular objects. But it is not suitable for outdoor, extremely hot environment or pressure tank and foam objects.

3、 Ultrasonic sensors can be applied in food processing plants to achieve closed-loop control systems for plastic packaging inspection. Combined with new technology, it can detect in humid environments such as bottle washing machines, noisy environments, and environments with extremely drastic temperature changes.

4、 Ultrasonic sensors can be used to detect liquid levels, transparent objects and materials, control tension, and measure distance. They are mainly used in equipment transportation for packaging, bottle making, material handling, coal inspection, plastic processing, and the automotive industry. Ultrasonic sensors can be used for process monitoring to improve product quality, detect defects, determine presence or absence, and other aspects.

Using ultrasonic sensor technology to prevent stepping on the wrong pedal

Nissan has developed a feature to prevent the vehicle from accelerating by accidentally stepping on the accelerator when braking. When using cameras and ultrasonic sensors to infer the situation of "parking in the parking lot", if the driver steps on the accelerator, they will forcefully brake. This technology is expected to be put into practical use within 2-3 years. Ultrasonic sensor technology was developed to prevent accidents caused by stepping on the wrong brake and accelerator while parking in a parking lot.

This technology is achieved by using four cameras equipped on the front, rear, left, and right sides of the vehicle, as well as eight ultrasonic sensors equipped on the front bumper and rear bumper respectively. The four cameras use the "surround view display" camera that displays a panoramic view of the vehicle's surroundings. Using cameras to identify white lines and infer that the car is located in the parking lot, and using ultrasonic sensors to measure the distance between the car and surrounding obstacles to determine the timing of braking.

Preventing accidents caused by stepping on the wrong brake and accelerator is implemented in two steps. When the driver wants to park in the parking lot, if they press the accelerator, they first reduce the speed to creep speed, use the icon on the dashboard to indicate danger, and sound an alarm. If the driver continues to press the accelerator and is about to hit a wall or other object, force the brake. The timing of braking is to ensure that the car can stop when it is about 20-30cm away from the obstacle.

working principle

People can hear sound due to the vibration of objects, with frequencies ranging from 20Hz to 20KHZ. Waves above 20KHZ are called ultrasonic waves, while those below 20Hz are called infrasound waves. The commonly used ultrasonic frequencies range from tens of KHZ to tens of MHZ.

Ultrasonic waves are a type of mechanical oscillation in elastic media, which can take two forms: transverse waves (transverse waves) and longitudinal waves (longitudinal waves). Vertical oscillation is mainly used in industrial applications. Ultrasonic waves can propagate in gases, liquids, and solids at different speeds. In addition, it also exhibits refraction and reflection phenomena, and undergoes attenuation during propagation. Ultrasonic waves propagate in the air at a lower frequency, usually several tens of KHZ, while in solids and liquids, the frequency can be higher. It decays quickly in air, but propagates less and farther in liquids and solids. By utilizing the characteristics of ultrasound, various ultrasound sensors can be made, coupled with different circuits, to produce various ultrasound measuring instruments and devices, which have been widely used in communication, medical appliances, and other fields.

The main materials for ultrasonic sensors are piezoelectric crystals (electrostriction) and nickel iron aluminum alloys (magnetostriction). Materials for electrostriction include lead zirconate titanate (PZT) and others. The ultrasonic sensor composed of piezoelectric crystals is a reversible sensor that can convert electrical energy into mechanical oscillations to generate ultrasonic waves. At the same time, when it receives ultrasonic waves, it can also be converted into electrical energy, so it can be divided into a transmitter or a receiver. Some ultrasonic sensors can be used for both transmission and reception. Here we only introduce small ultrasonic sensors, which have slight differences in transmission and reception. They are suitable for propagation in the air and generally operate at frequencies of 23-25KHZ and 40-45KHZ. This type of sensor is suitable for ranging, remote control, anti-theft and other purposes. This type includes T/R-40-16, T/R-40-12, etc. (where T represents transmission, R represents reception, 40 represents frequency of 40KHZ, and 16 and 12 represent their outer diameter dimensions in millimeters). There is another type of sealed ultrasonic sensor (MA40EI type). Its characteristics are waterproof (but cannot be placed in water), it can be used as a material level and proximity switch, and its performance is good. There are three basic types of ultrasonic applications, transmission type is used for remote controllers, anti-theft alarms, automatic doors, proximity switches, etc; Separate reflection type is used for distance measurement, liquid level or material level; Reflective type is used for material inspection, thickness measurement, etc.

It consists of a transmitting sensor (or wave transmitter), a receiving sensor (or wave receiver), a control part, and a power supply part. The transmitter sensor consists of a transmitter and a ceramic oscillator transducer with a diameter of about 15mm. The transducer converts the electrical vibration energy of the ceramic oscillator into super energy and radiates it into the air; The receiving sensor consists of a ceramic oscillator transducer and an amplification circuit. The transducer receives waves and generates mechanical vibrations, which are converted into electrical energy and used as the output of the sensor receiver to detect the transmitted ultrasonic signals. In practical use, the ceramic oscillator used as a transmitting sensor can also be used as a receiving sensor's ceramic oscillator. The control part mainly controls the frequency, duty cycle, sparse modulation, counting, and detection distance of the pulse chain emitted by the transmitter.

Work Procedure

If a high-frequency voltage of 40KHz is applied to a piezoelectric ceramic plate (bicrystal oscillator) with a resonant frequency of 40KHz inside the transmitting sensor, the piezoelectric ceramic plate will elongate and shorten according to the polarity of the applied high-frequency voltage, thus transmitting ultrasonic waves with a frequency of 40KHz. The ultrasonic waves propagate in a dense form (the degree of density can be modulated by the control circuit) and are transmitted to the wave receiver. The receiver utilizes the principle of piezoelectric effect used in pressure sensors, which applies pressure to the piezoelectric element to induce strain, resulting in a 40KHz sine voltage with one side being the "+" pole and the other side being the "-" pole. Due to the small amplitude of the high-frequency voltage, amplification is necessary. Ultrasonic sensors enable drivers to safely reverse by detecting any obstacles on or near the reverse path and issuing timely warnings. The designed detection system can provide both auditory and visual warnings with both sound and light, indicating the detection of the distance and direction of obstacles in blind spots. In this way, whether parking or driving in narrow areas, with the help of the reverse obstacle detection system, the driver's psychological pressure will be reduced and necessary actions can be taken with ease.

Working mode

Ultrasonic sensors use acoustic media for non-contact and wear-resistant detection of the object being tested. Ultrasonic sensors can detect transparent or colored objects, metal or non-metal objects, solid, liquid, and powder substances. Its detection performance is almost unaffected by any environmental conditions, including smoke and dust environments and rainy days.

Detection mode

Ultrasonic sensors mainly adopt a direct reflection detection mode. The detected object located in front of the sensor partially emits the emitted sound waves back to the sensor's receiver, thereby enabling the sensor to detect the detected object.

Some ultrasonic sensors also adopt a paired detection mode. A set of paired ultrasonic sensors includes a transmitter and a receiver, with continuous "listening" between the two. The detected object located between the receiver and transmitter will block the receiver from receiving the emitted sound waves, causing the sensor to generate a switch signal.

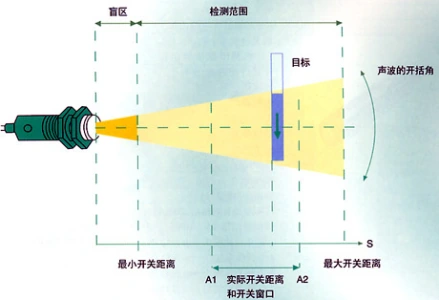

Detection range

The detection range of ultrasonic sensors depends on the wavelength and frequency used. The longer the wavelength, the smaller the frequency, and the longer the detection distance. For example, compact sensors with millimeter level wavelengths have a detection range of 300-500mm, and sensors with wavelengths greater than 5mm can achieve a detection range of 8m. Some sensors have a narrow 6 º sound wave emission angle, making them more suitable for precise detection of relatively small objects. Other sensors with sound wave emission angles between 12 º and 15 º can detect objects with larger inclinations. In addition, we also have external probe type ultrasonic sensors, with corresponding electronic circuits located inside the conventional sensor housing. This structure is more suitable for detecting situations where installation space is limited.

adjust

Almost all ultrasonic sensors can adjust the near and far points or measurement range of the switch output. Objects outside the set range can be detected, but will not trigger a change in output state. Some sensors have different adjustment parameters, such as the response time and echo loss performance of the sensor, as well as the setting adjustment of the working direction when the sensor is connected to the pump equipment.

Repetitive accuracy

Factors such as wavelength can affect the accuracy of ultrasonic sensors, with the most significant factor being the speed of sound waves that vary with temperature. Therefore, many ultrasonic sensors have temperature compensation characteristics. This feature enables analog output type ultrasonic sensors to achieve a repeatability accuracy of up to 0.6mm over a wide temperature range.

Output function

All series of ultrasonic sensors have switch output products. Some products also have two switch outputs (such as minimum and maximum liquid level control). Most product lines offer products with analog current or analog voltage outputs.

Noise suppression

The noise such as metal tapping and roaring will not affect the parameter assignment of ultrasonic sensors, mainly due to the optimization of frequency range and patented noise suppression circuits.

Synchronization function

The synchronization function of ultrasonic sensors can prevent interference. They achieve synchronization function by simply connecting their respective synchronization lines. They simultaneously emit sound wave pulses, work like a single sensor, and have an extended detection angle.

Alternating work

Ultrasonic sensor ultra long scanning type

Ultrasonic sensors that work in an alternating manner are independent of each other and do not affect each other. The more sensors that work in an alternating manner, the lower the switching frequency of the response.

Testing conditions

Ultrasonic sensors are particularly suitable for working in media such as air. This type of sensor can also work in other gas media, but requires sensitivity adjustment.

blind area

Direct reflection ultrasonic sensors cannot reliably detect some objects located in the front section of the ultrasonic transducer. Therefore, the area between the ultrasonic transducer and the starting point of the detection range is called a blind zone. The sensor must remain unobstructed in this area.

Temperature and humidity

Air temperature and humidity can affect the travel time of sound waves. For every 20 º C increase in air temperature, the detection distance can increase by up to 3.5%. Under relatively dry air conditions, an increase in humidity will result in a maximum increase of 2% in sound velocity.

air pressure

Under normal circumstances, an atmospheric change of ± 5% (selecting a fixed reference point) will result in a change of ± 0.6% in the detection range. In most cases, sensors can be used without any issues at a pressure of 5 Bar.

airflow

The change in airflow will affect the speed of sound. However, the impact caused by airflow speeds up to 10m/s is negligible. Under conditions where air eddies are common, such as for hot metals, it is recommended not to use ultrasonic sensors for detection, as it is very difficult to calculate the echo of distorted sound waves.

Standard test substance

Use a square sound reflector plate for calibrating the rated switch distance sn.

1mm thickness

Verticality: perpendicular to the axis of the sound beam.

Protection level

The shell is resistant to solid particles and waterproof.

IP65: completely dust-proof; Intrusion of waterproof columns.

IP67: completely dust-proof; Immersing at a depth of 1m under constant temperature and leaving for 30 minutes can effectively protect.

IP69K: Compliant with DIN40050-9 based on EN60529

Pump function

Dual position control can be implemented, such as the pump in and pump out function of a liquid level control system. When a measured object moves away from the sensor and reaches the far point of the detection range, an action is output. When the measured object approaches the sensor and reaches the set proximity point within the detection range, output the opposite action.

System composition

Ultrasonic sensors mainly consist of the following four parts:

Transmitter: Generate ultrasonic waves through vibration of a transducer (usually a ceramic product with a diameter of about 15 mm) and radiate them into the air.

Receiver: When the oscillator receives ultrasonic waves, it generates corresponding mechanical vibrations based on the ultrasonic waves and converts them into electrical energy as the output of the receiver.

Control part: By using integrated circuits to control the ultrasonic transmission of the transmitter, and determine whether the receiver has received the signal (ultrasonic), as well as the size of the received signal.

Power supply: Ultrasonic sensors usually use an external DC power supply with a voltage of DC12V ± 10% or 24V ± 10%, which is supplied to the sensor through an internal voltage regulator circuit.

Testing method

According to the characteristics such as volume, material, and mobility of the detected object, ultrasonic sensors use different detection methods. There are four common detection methods:

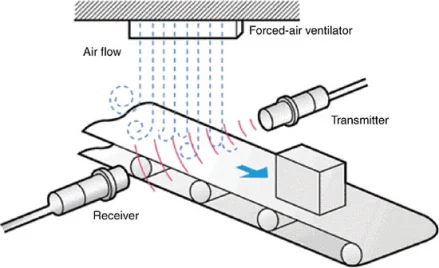

Penetrating type: The transmitter and receiver are located on both sides, and when the detected object passes between them, detection is carried out based on the attenuation (or obstruction) of the ultrasonic waves.

Limited distance type: The transmitter and receiver are located on the same side, and when a detected object passes through within a limited distance, detection is performed based on reflected ultrasonic waves.

Limited range type: The transmitter and receiver are located at the center of the limited range, the reflector is located at the edge of the limited range, and the attenuation value of the reflected wave when there is no obstruction from the detected object is used as the reference value. When a detected object passes through within a limited range, detection is performed based on the attenuation of the reflected wave (comparing the attenuation value with the reference value).

Regression reflection type: The transmitter and receiver are located on the same side, with the detection object (flat object) as the reflection surface, and detection is performed based on the attenuation of the reflected wave.

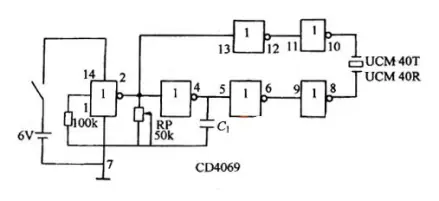

Check for quality

There is no significant response when testing ultrasonic sensors directly with a multimeter. To test the quality of ultrasonic sensors, an audio oscillation circuit can be built. When C1 is 390O μ F, an audio signal of about 1.9kHz can be generated between the ⑧ and ⑩ pins of the inverter. Connect the ultrasonic sensor (transmitter and receiver) to be tested between pin 8 and pin 10; If the sensor can produce audio sound, it can be basically determined that this ultrasonic sensor is good.

Note: When C1=3900 μ F, it is around 1.9kHZ; When C1=0.1 μ F, it is about 0.76kHz.

Liquid level testing

The basic principle of ultrasonic liquid level measurement is that the ultrasonic pulse signal emitted by the ultrasonic probe propagates in the gas and is reflected at the interface between air and liquid. After receiving the echo signal, the round-trip propagation time of the ultrasonic wave can be calculated to convert the distance or liquid level height. The ultrasonic measurement method has many advantages that cannot be compared to other methods: (1) it has no mechanical transmission components and does not come into contact with the measured liquid, belonging to non-contact measurement. It is not afraid of electromagnetic interference, strong corrosive liquids such as acid and alkali, etc. Therefore, it has stable performance, high reliability, and long service life; (2) Its short response time enables convenient real-time measurement without lag.

The operating frequency of the ultrasonic sensor used in the system is around 40kHz. The ultrasonic pulse is emitted by the transmitting sensor, transmitted to the liquid surface and reflected before returning to the receiving sensor. The time required for the ultrasonic pulse to be transmitted and received is measured. Based on the sound velocity in the medium, the distance between the sensor and the liquid surface can be obtained to determine the liquid level. Considering the influence of environmental temperature on the propagation speed of ultrasonic waves, the propagation speed is corrected through temperature compensation to improve measurement accuracy. The calculation formula is:

V=331.5+0.607T (1)

In the formula: V is the propagation speed of ultrasonic waves in air; T is the ambient temperature.

S=V ×t/2=V×(t1-t0)/2 (2)

In the formula: S is the measured distance; T is the time difference between emitting ultrasound pulses and receiving their echoes; T1 is the time of ultrasonic echo reception; T0 is the time of ultrasonic pulse emission. The capture function of MCU can easily measure time t0 and time t1. According to the above formula, the measured distance S can be obtained by software programming. Due to the use of a mixed signal processor with SOC characteristics in the MCU of this system, which integrates a temperature sensor internally, temperature compensation of the sensor can be easily achieved using software.

Other information

distinguish

The difference between ultrasonic sensors and sonar sensors

Sonar sensors and ultrasonic sensors are two commonly heard detection devices. Many people believe that these two are one type of sensor. What is the difference between these two types of sensors?

Sonar sensors directly detect and recognize objects in the water and the contours of the bottom of the water. Sonar sensors emit a sound wave signal that reflects back when encountering an object, and calculate its distance and position based on the reflection time and waveform. Ultrasonic waves are mechanical waves with a vibration frequency higher than sound waves, generated by the vibration of a transducer chip under voltage excitation. They have the characteristics of high frequency, short wavelength, small diffraction phenomenon, especially good directionality, and the ability to propagate directionally as rays. Sonar sensors are mainly used to detect organisms, such as detecting which organisms are underwater and how large they are. The device you often hear about for detecting water monsters is sonar sensors.

Ultrasonic waves have a great ability to penetrate liquids and solids, especially in opaque solids, where they can penetrate depths of several tens of meters. Ultrasonic waves will produce significant reflections when encountering impurities or interfaces, forming echoes, and can produce Doppler effects when encountering moving objects. Therefore, ultrasonic testing is widely used in industry, national defense, biomedical and other fields. Ultrasonic sensors are sensors developed using the characteristics of ultrasonic waves. In the industrial field, the typical applications of ultrasound are non-destructive testing of metals and ultrasonic thickness measurement. The application of ultrasonic sensors in medicine is mainly for diagnosing diseases, and it has become an indispensable diagnostic method in clinical medicine.

matters needing attention

1: To ensure reliability and long service life, do not use sensors outdoors or in places above rated temperature.

2: Due to the fact that ultrasonic sensors use air as the transmission medium, reflection and refraction at the boundary may cause misoperation when the local temperature is different, and the detection distance may also change when the wind blows. Therefore, sensors should not be used next to equipment such as forced ventilation fans.

3: The jet emitted by the nozzle has multiple frequencies, which can affect the sensor and should not be used near the sensor.

4: The water droplets on the surface of the sensor shorten the detection distance.

5: Materials such as fine powder and cotton yarn cannot be detected when absorbing sound (reflective sensors).

6: Sensors cannot be used in vacuum or explosion-proof areas.

7: Do not use sensors in areas with steam; The atmosphere in this area is uneven. It will generate temperature gradients, leading to measurement errors.

Expose issues

The application principle of ultrasonic sensors is simple, convenient, and the cost is also very low. However, ultrasonic sensors all have some drawbacks, such as reflection issues, noise, and cross-over problems.

Reflection problem

If the detected object is always at the appropriate angle, the ultrasonic sensor will obtain the correct angle. Unfortunately, in practical use, very few detected objects can be accurately detected.

There may be several types of errors that may occur:

Triangular error

When the measured object is at a certain angle to the sensor, there is a triangular error between the detected distance and the actual distance.

Specular reflection

This problem is the same as the reflection of light learned in high school physics. At a specific angle, the emitted sound waves are reflected off the smooth surface of an object, making it impossible to generate echoes and thus unable to produce distance readings. At this point, the ultrasonic sensor will ignore the presence of this object.

Multiple reflections

This phenomenon is quite common when detecting corners of walls or similar structures. The sound wave undergoes multiple bounces before being received by the sensor, so the actual detection value is not the true distance value.

These problems can be solved by using multiple ultrasonic coils arranged at a certain angle. By detecting the return values of multiple ultrasonic waves, the correct readings can be selected.

noise

Although the operating frequency of most ultrasonic sensors is 40-45KHz, much higher than the frequency that humans can hear. But the surrounding environment can also produce noise of similar frequency. For example, the motor generates a certain high frequency during rotation, the high-frequency noise generated by the friction of the wheels on relatively hard ground, the shaking of the robot itself, and even when there are multiple robots, the sound waves emitted by other robot ultrasonic sensors can cause the sensors to receive incorrect signals.

This problem can be solved by encoding the emitted ultrasound waves, such as emitting a set of different lengths of sound waves, and only calculating the distance when the detection head detects the same combination of sound waves. This can effectively avoid misreading caused by environmental noise.

Cross disciplinary issues

The cross problem is caused when multiple ultrasonic sensors are installed at a certain angle on a robot. The sound waves emitted by ultrasonic wave X are reflected by the mirror and obtained by sensors Z and Y. At this point, Z and Y will calculate the distance value based on this signal, making it impossible to obtain accurate measurements.

The solution can be achieved by encoding the signals emitted by each sensor. Let each ultrasonic sensor only listen to its own voice.