Electromagnetic flowmeters (EMF for short) are new flow measurement instruments that developed rapidly in the 1950s and 1960s with the development of electronic technology. Electromagnetic flowmeters are instruments that use the principle of electromagnetic induction to measure the flow of conductive fluids based on the electromotive force induced when the conductive fluid passes through an external magnetic field.

structure:

The structure of the electromagnetic flowmeter is mainly composed of magnetic circuit system, measuring tube, electrode, casing, lining and converter.

Magnetic circuit system: Its function is to generate a uniform DC or AC magnetic field. The DC magnetic circuit is realized by permanent magnets. Its advantage is that the structure is relatively simple and is less disturbed by the AC magnetic field. However, it is easy to polarize the electrolyte liquid passing through the measuring conduit, so that the positive electrode is surrounded by negative ions and the negative electrode is surrounded by positive ions, that is, the polarization phenomenon of the electrode, and the internal resistance between the two electrodes increases, which seriously affects the normal operation of the instrument. When the diameter of the pipeline is large, the permanent magnet is also large, bulky and uneconomical, so the electromagnetic flowmeter generally uses an alternating magnetic field, and is excited by a 50HZ power frequency power supply.

Measuring conduit: Its function is to allow the conductive liquid to pass through. In order to make the magnetic flux be shunted or short-circuited when the magnetic lines of force pass through the measuring conduit, the measuring conduit must be made of non-magnetic, low-conductivity, low-thermal conductivity and certain mechanical strength materials. Non-magnetic stainless steel, fiberglass, high-strength plastic, aluminum, etc. can be selected.

Electrode: Its function is to lead out an induced potential signal proportional to the measured value. The electrode is generally made of non-magnetic stainless steel and is required to be flush with the lining so that the fluid can pass through without obstruction. It should be installed in the vertical direction of the pipeline to prevent sediment from accumulating on it and affecting the measurement accuracy.

Shell: Made of ferromagnetic material, it is the outer cover of the excitation coil of the distribution system and isolates the interference of the external magnetic field.

Lining: There is a complete electrical insulation lining on the inner side of the measuring conduit and the flange sealing surface. It is in direct contact with the measured liquid, and its function is to increase the corrosion resistance of the measuring conduit and prevent the induced potential from being short-circuited by the metal measuring conduit wall. The lining material is mostly corrosion-resistant, high-temperature-resistant, wear-resistant polytetrafluoroethylene plastic, ceramic, etc.

Converter: The induced potential signal generated by the flow of liquid is very weak and is greatly affected by various interference factors. The role of the converter is to amplify the induced potential signal and convert it into a unified standard signal and suppress the main interference signal. Its task is to convert the induced potential signal Ex detected by the electrode into a unified standard DC signal after amplification.

Features:

1. The measurement is not affected by changes in fluid density, viscosity, temperature, pressure and conductivity;

2. There are no obstructive flow parts in the measuring tube, no pressure loss, and the straight pipe section requirement is low. It has unique adaptability to slurry measurement;

3. Reasonable selection of sensor lining and electrode materials, that is, good corrosion resistance and wear resistance;

4. The converter adopts a novel excitation method with low power consumption, stable zero point and high accuracy. The flow range can reach 150:1;

5. The converter can be integrated or separated with the sensor;

6. The converter adopts a 16-bit high-performance microprocessor and a 2x16 LCD display, which is convenient for parameter setting and reliable programming;

7. The flow meter is a bidirectional measurement system with three integrators: forward total, reverse total and difference total; it can display forward and reverse flow and has multiple outputs: current, pulse, digital communication, HART;

8. The converter adopts surface mounting technology (SMT) and has self-test and self-diagnosis functions;

9. The measurement accuracy is not affected by changes in fluid density, viscosity, temperature, pressure and conductivity. The sensor induced voltage signal is linearly related to the average flow rate, so the measurement accuracy is high.

10. There is no flow obstruction in the measuring pipeline, so there is no additional pressure loss; there are no moving parts in the measuring pipeline, so the sensor life is extremely long.

11. Since the induced voltage signal is formed in the entire space full of magnetic field and is the average value on the pipeline surface, the sensor requires a shorter straight pipe section, which is 5 times the diameter of the pipeline.

12. The converter adopts the latest and most advanced single-chip microcomputer (MCU) and surface mount technology (SMT) in the world, with reliable performance, high precision, low power consumption, stable zero point, and convenient parameter setting. Click the Chinese display LCD to display the cumulative flow, instantaneous flow, flow rate, flow percentage, etc.

13. The bidirectional measurement system can measure forward flow and reverse flow. The special production process and high-quality materials are used to ensure that the performance of the product remains stable for a long time.

Classification:

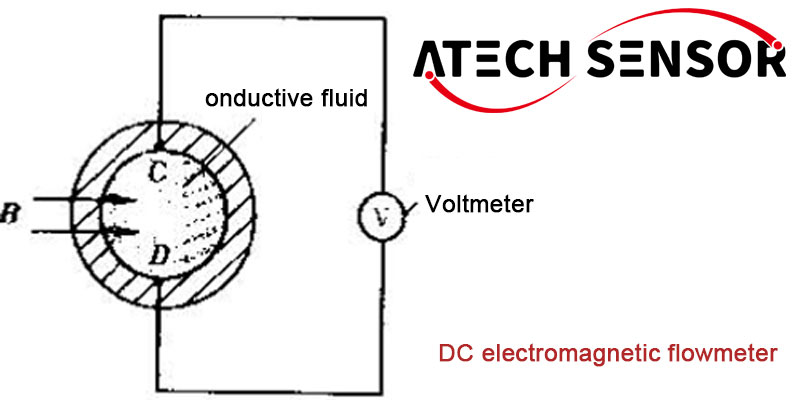

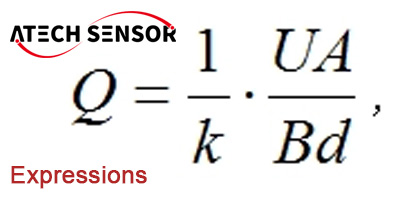

According to the different types of external magnetic fields, electromagnetic flowmeters are mainly divided into two types: DC type and induction type. The DC type electromagnetic flowmeter (as shown in the figure) has an external constant magnetic field B perpendicular to the pipe axis, and two electrodes are installed at C and D to measure the electromotive force U induced when the fluid crosses the magnetic field. The flow rate Q can be calculated using the following formula:

Where A is the cross-sectional area of the pipe; d is the pipe diameter; k is the correction factor, which is used to correct the influence of factors not taken into account when deriving the formula (such as the fact that the flow velocity in the flowmeter pipe is not uniform). In ordinary flowmeters, k is about 0.8, but for electromagnetic flowmeters of specific size and for specific working conditions, the k value is calibrated by the volumetric method (the volume flowing in a certain period of time). The magnetic field can be generated by permanent magnets, and the magnet material is generally aluminum-nickel-cobalt alloy. When the flow rate is large, due to the large pipe diameter, a coreless excitation winding is used, and a normal DC current is passed through it to generate an approximately uniform magnetic field.

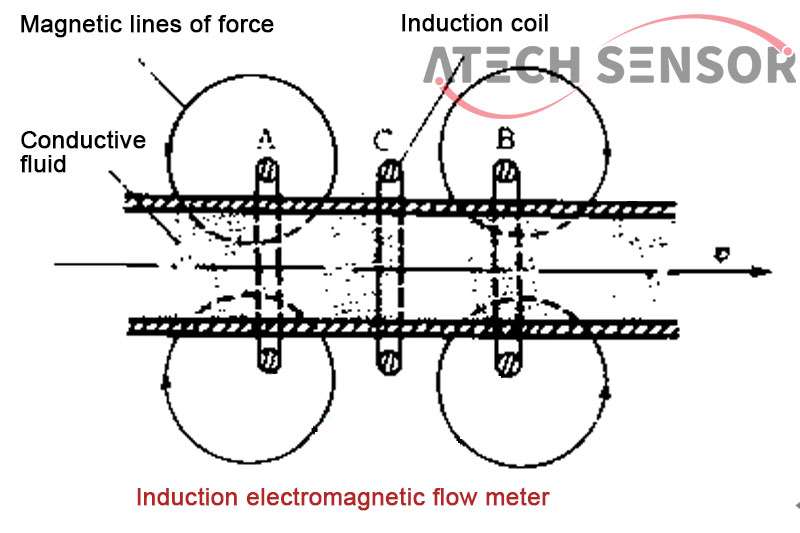

Induction electromagnetic flowmeter In the case of high temperature of the measured fluid or strong corrosion to the electrode, an induction electromagnetic flowmeter can be used (as shown in the figure). A and B are two AC excitation windings with equal number of turns (the figure shows a cross section). The windings are connected in series, but the current directions are opposite. When the fluid is stationary, the synthetic magnetic flux through the induction coil C is zero, so there is no induced alternating electromotive force in the coil. When the fluid flows, an alternating electromotive force is generated in the induction coil, and its magnitude is proportional to the flow rate. Based on this principle, there are many modification schemes. For example, an excitation winding is used, and an induction coil with opposite directions is placed on each of its symmetrical sides and connected in series. When the fluid flows, the magnetic lines of force move in the direction of flow, so that the electromotive force generated in the induction coils on both sides is not zero, which can indirectly indicate the size of the flow.

There are no other parts in the pipeline of the electromagnetic flowmeter, so in addition to measuring the flow of conductive fluids, it can also be used to measure the flow of non-conductive liquids of various viscosities (in which easily ionized substances are added). Electromagnetic flowmeters are often used in the nuclear energy industry.

Electromagnetic flowmeters are divided into split type electromagnetic flowmeters and integrated type electromagnetic flowmeters according to the display mode. The series nominal diameter is DN15~DN3000.

The split type electromagnetic flowmeter is an inductive instrument that measures the volume flow of conductive media in the pipe according to Faraday's law of electromagnetic induction. It adopts single-chip embedded technology to realize digital excitation. At the same time, it adopts CAN field bus on the electromagnetic flowmeter. It is the first domestic innovation and the technology has reached the domestic leading level.

While meeting the requirements of on-site display, the split type electromagnetic flowmeter can also output 4~20mA current signal for recording, adjustment and control. It has been widely used in industrial technology and management departments such as chemical industry, environmental protection, metallurgy, medicine, papermaking, water supply and drainage.

In addition to measuring the flow of general conductive liquids, the split type electromagnetic flowmeter can also measure the volume flow of liquid-solid two-phase flow, high viscosity liquid flow and salt, strong acid and strong alkali liquids.

The integrated type electromagnetic flowmeter is formulated according to Faraday's law of electromagnetic induction and is used to measure the volume flow of conductive fluids. Due to its unique characteristics, it has been widely used in the measurement of various conductive liquids in industry. It is mainly used in chemical, papermaking, food, textile, metallurgy, environmental protection, water supply and drainage and other industries. It can realize system control when matched with computers.

1. The electromagnetic flowmeter has no moving parts or flow-blocking parts, which will not cause pressure loss, wear, blockage and other problems.

2. The electromagnetic flowmeter is a volume flow measurement instrument. During the measurement process, it is not affected by the temperature, viscosity, density and conductivity (within a certain range) of the measured medium.

3. The electromagnetic flowmeter has a wide range, up to 1:100. In addition, the electromagnetic flowmeter is only proportional to the average flow velocity of the measured medium, and has nothing to do with the axisymmetric flow state (laminar flow or turbulent flow).

4. The electromagnetic flowmeter has no mechanical inertia, is sensitive to reaction, can measure instantaneous pulsating flow, and has good linearity. Therefore, the measurement signal can be directly converted into a standard signal output by a converter. LD-T type can indicate on-site, and LD type can be transmitted over long distances.

Instrument installation:

Simply put, the electromagnetic flowmeter is composed of a flow sensor transmitter. The installation requirement of the electromagnetic flowmeter is that it must be installed at the lowest point of the pipeline or the vertical section of the pipeline, but it must be installed in a full pipe. The straight pipe section requires 5D in the front and 3D in the back, so as to ensure the use of the electromagnetic flowmeter and the accuracy requirements.

The measurement principle of the electromagnetic flowmeter does not depend on the characteristics of the flow. If there is a certain amount of turbulence and vortex in the pipeline generated in the non-measurement area (such as elbows, tangential flow restrictions or half-open stop valves upstream), it has nothing to do with the measurement. If there is a steady-state vortex in the measurement area, it will affect the stability and accuracy of the measurement. At this time, some measures should be taken to stabilize the flow velocity distribution:

● Increase the length of the straight pipe section before and after

● Use a flow stabilizer

●Reduce the cross section of the measuring point.

1. Requirements for the external environment

●The flowmeter should not be installed in places with large temperature changes or high temperature radiation from the equipment. If it must be installed, insulation and ventilation measures must be taken.

● The flowmeter is best installed indoors. If it must be installed outdoors, it should be protected from rain, water accumulation and sun exposure. Moisture and sun protection measures must be taken.

●The flowmeter should not be installed in an environment containing corrosive gases. If it must be installed, ventilation measures must be taken.

●In order to facilitate installation, maintenance and maintenance, there must be sufficient installation space around the flowmeter.

●The flowmeter installation site should avoid magnetic fields and strong vibration sources. If the pipeline vibrates strongly, there should be supports on both sides of the flowmeter to fix the pipeline.

2. Pipeline electromagnetic flowmeter

2.1 Requirements for straight sections

In order to improve the influence of eddy current and flow field distortion, there are certain requirements for the length of the straight pipe sections before and after the flow meter is installed, otherwise it will affect the measurement accuracy (rectifiers can also be installed, and try to avoid installing them near the regulating valve and after the half-open valve).

2.2 Requirements for process pipes

The flowmeter has certain requirements for the upstream and downstream process pipes of the installation point, otherwise it will affect the measurement accuracy.

●The inner diameter of the upstream and downstream process pipes is the same as the inner diameter of the sensor, and should meet the following requirements: 0.98DN≤D≤1.05DN (where DN is the inner diameter of the sensor, and D is the inner diameter of the process pipe)

●The process pipe and the sensor must be concentric, and the coaxial deviation should not exceed 0.05DN

2.3 Requirements for bypass pipe

In order to facilitate the maintenance of the flow meter, it is best to install a bypass pipe for the flow meter. In addition, for heavily polluted fluids and flow meters that need to be cleaned but the fluid cannot be stopped, a bypass pipe must be installed.

● Convenient for the maintenance of the flow meter

●Must be installed for heavily polluted fluids

●The fluid cannot be stopped and the flow meter needs to be cleaned

3. Installation requirements for insertion electromagnetic flowmeter

3.1 Requirements for straight pipe sections

Inlet/outlet straight pipe sections: inlet should be ≥10×DN; outlet should be ≥5×DN

3.2 Requirements for docking location

In order to make the instrument work reliably, improve the measurement accuracy, and not be disturbed by external parasitic potential, the sensor should be well grounded, and the grounding resistance should be less than 10. (If the metal pipe is well grounded, there is no need to set up a special grounding device)

3.3 Requirements for installation position are as shown in the figure

The insertion electromagnetic flowmeter varies according to the on-site pipeline conditions. The flowmeter without a ball valve should be installed on a non-pressure pipeline (that is, for non-pressure installation, a flowmeter without a ball valve can be selected), and a hole with a diameter of 50 is opened on the pipeline, and the connecting welded pipe is prepared to be welded to the opening of the pipeline; for occasions that require continuous flow loading and unloading or do not allow medium overflow, a ball valve must be installed, that is, an insertion electromagnetic flowmeter with a ball valve structure is selected; a hole with a diameter of 50 is opened on the pipeline, and the connecting welded pipe is prepared to be welded to the opening of the pipeline.

Electromagnetic flowmeters are widely used in sewage, fluorine chemicals, production water, tap water industry, medicine, steel and many other aspects. Due to the principle, it can only measure conductive liquids. Although it is much better than other types of flowmeters in terms of reliability and stability, customers still encounter some problems in actual use. Let me talk about the selection and installation of electromagnetic flowmeters in detail below:

1. Like other flowmeters, although the measurement range ratio of electromagnetic flowmeter is 30:1, which is higher than vortex flowmeter and differential pressure flowmeter, it is also limited. When many customers order the meter, they often compare it with the water meter, thinking that it can measure very low flow rate. Under normal circumstances, it can only measure 0.1m/s. It is difficult for the electromagnetic flowmeter to measure correctly below this flow rate. Therefore, the flow range ratio should be clarified at the beginning of the order. When ordering, you cannot order according to the original pipeline diameter. It is best to determine the instrument diameter according to your actual flow.

2. Like other flow meters, electromagnetic flow meters also have requirements for straight pipes before and after installation, but the requirements are lower than those of other types of flow meters, but the most critical point must be met: full pipe, full pipe again. If the pipe is not full, it is easy to cause the flow meter to jump randomly.

3. Like other flow meters, electromagnetic flow meters also have protection levels. Generally, the protection level of the integrated type is IP65, and the split type is IP68 (for sensors). If the customer has requirements for the installation environment of the instrument, the installation location is in an underground well or other humid places, it is recommended that the customer choose a split type. To avoid damage to the instrument due to wrong selection.

4. Electromagnetic flow meters can measure corrosive liquids, but customers must correctly provide other measurement medium properties at the beginning of the order to avoid errors in electrode selection during selection, which will cause the sensor to be scrapped during later use, causing inconvenience and economic losses to customers.

5. Although the electromagnetic flow meter has good reliability and is generally not damaged, due to its principle, the sensor electrode surface has been in contact with the liquid. Over time, the electrode surface is more susceptible to contamination. Therefore, in general, if the customer has the conditions to dismantle the electromagnetic flowmeter, it is recommended to dismantle it and clean the electrodes once a year to a year and a half to ensure the measurement accuracy of the flowmeter. Any instrument needs "maintenance", and the electromagnetic flowmeter is no exception.

6. When the main pipeline is a vertical pipeline, in general, the water flow is required to be from bottom to top, and try not to be from top to bottom. The latter is likely to cause large flow fluctuations. In addition to full pipe installation, this is also very important, and the second is the distance between the front and rear straight pipes.

Choose a place that is easy to maintain and convenient for activities. The flowmeter should be installed at the rear end of the water pump and must not be installed on the suction side; the valve should be installed on the downstream side of the flow.

Measuring range:

The electromagnetic flowmeter has a large measurement range, usually 20:1~50:1, and a wide range of optional flow rates. The caliber range of the electromagnetic flowmeter is wider than that of other flow meters, ranging from a few millimeters to 3 meters. It can measure forward and reverse bidirectional flow, and can also measure pulsating flow, as long as the pulsating frequency is much lower than the excitation frequency. The output of the meter is linear in nature. It is easy to select the material variety of the fluid contact parts, and can be applied to corrosive fluids. Since the electromagnetic flowmeter has a much greater chance of measuring suspended solids or dirty bodies than other flow meters, the probability of failure caused by the inner wall adhesion layer is relatively high. If the conductivity of the adhesion layer is similar to that of the liquid, the meter can still output signals normally, but it changes the flow area, forming a hidden fault of measurement error; if it is a high conductivity adhesion layer, the electromotive force between the electrodes will be short-circuited; if it is an insulating adhesion layer, the electrode surface will be insulated and the measurement circuit will be disconnected. The latter two phenomena will make the meter inoperable.

Main Products:

The intelligent electromagnetic flowmeter uses a backlit wide temperature dot matrix LCD display. All displays are in Chinese. It has many practical functions, which is particularly convenient for users to operate and reduce unnecessary troubles and errors.

Fast delivery, low cost and easy maintenance.

How does the electromagnetic flowmeter resist interference?

When measuring large interference signals such as pulp/ore pulp, the 8707 high signal flow tube can be used to improve the signal strength.

The intelligent electromagnetic flowmeter AFLD is designed with a fully intelligent principle, which is very different from the old or fake intelligent electromagnetic flowmeters produced by some domestic companies in terms of measurement accuracy, function, reliability and service life.

The service life of the electromagnetic flowmeter should be more than 10-20 years, so we fully consider this point when designing. We are very careful about every detail from the sensor to the converter. We are very particular about every link from design, material selection, process, production, testing, etc. We design and customize the most advanced production line for special electromagnetic flowmeters in China to ensure the long-term quality of the product.

The insertion electromagnetic flowmeter is composed of an insertion electromagnetic flow sensor (referred to as the sensor) and an electromagnetic flow converter (referred to as the converter) (referred to as the flowmeter). It is an instrument used to measure the volume flow of various conductive liquids in pipelines. The insertion electromagnetic flowmeter is used to measure the flow of conductive fluids in tap water, steel, petroleum, chemical, electric power, industry, water conservancy and other departments, and can also measure corrosive conductive liquids such as acids, alkalis and salts.

Matters needing attention:

1. Accuracy level and function Choose the instrument accuracy level according to the measurement requirements and the occasion of use to achieve economical and cost-effective. For example, for trade settlement, product handover and energy measurement, a higher accuracy level should be selected, such as 1.0, 0.5, or higher; for process control, different accuracy levels should be selected according to the control requirements; some occasions just detect the process flow, without precise control and measurement, you can choose a slightly lower accuracy level, such as 1.5, 2.5, or even 4.0, then you can choose a low-cost insertion electromagnetic flowmeter.

2. Measuring medium flow rate, instrument range and caliber When measuring general media, the full flow of the electromagnetic flowmeter can be selected within the range of 0.5-12m/s of the measured medium flow rate, which is a relatively wide range. The instrument specification (caliber) is not necessarily the same as the process pipeline. It should be determined whether the measurement flow range is within the flow rate range. That is, when the pipeline flow rate is low and cannot meet the flow meter requirements or the measurement accuracy cannot be guaranteed at this flow rate, it is necessary to reduce the instrument caliber to increase the flow rate in the pipe and obtain satisfactory measurement results.

3. Try to avoid ferromagnetic objects and equipment with strong electromagnetic fields to prevent the magnetic field from affecting the working magnetic field and flow signal of the sensor.

4. It should be installed in a dry and ventilated place as much as possible, avoid sun and rain, the ambient temperature should be -20 ~ + 60 ℃, and the relative humidity should be less than 85%.

5. There should be ample space around the flow meter for easy detection and maintenance.