Common types of liquid level meters

1, magnetic flap level meter

2, float level meter

3, steel to be level meter

4, radar level meter

5, magnetostrictive level meter

6, radio frequency conductivity level meter

7, tuning fork level meter

8, glass plate / glass tube level meter

9, hydrostatic level meter

10, pressure level transmitter

11, capacitance level meter

12, intelligent electric float level meter

13, float level meter

14, float levelTransmitter

15, electric contact level meter

16, magnetic two-color electronic level meter

17, external measurement level meter

18, hydrostatic level meter

19, ultrasonic level meter

20, differential pressure level meter (double flange level meter)

The working principle of the commonly used liquid level meter

1、Magnetic flip-plate level meter

Principle: Connector principle, according to the principle of buoyancy and magnetic coupling role of R & D and become, when the level of the vessel under test rise and fall, the permanent magnets within the float through the magnetic coupling to the magnetic flip-column indicator panel, so that the red and white flip-column flip 180 °, when the level rises the flip-column from white to red, when the level of a small drop in the flip-column by the red to white, the panel of the red-white junction for the actual height of the level of liquid in the container, so that the liquid level display.The junction of red and white on the panel is the actual height of the liquid level in the container, thus realizing liquid level display.

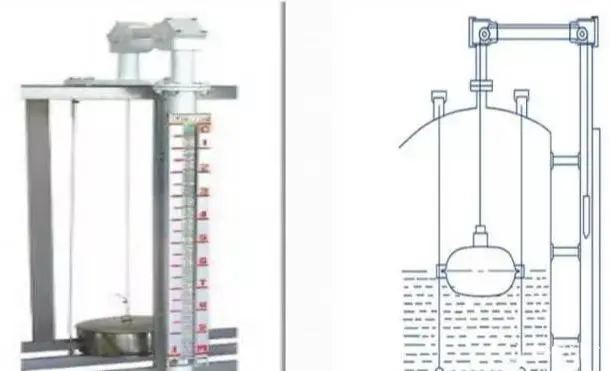

2、Float level meter

Float level meter structure is mainly based on the principle of buoyancy and static magnetic field design and production.The position of the float with magnets (referred to as float) in the measured medium is influenced by buoyancy: changes in the liquid level lead to changes in the position of the magnetic float.The magnets and sensors (reed switches) in the float act to change the number of components (e.g., fixed-value resistors) connected to the circuit, which in turn causes a change in the electrical quantity of the instrument circuit system.In other words, a change in the position of the magnetic float causes a change in the electrical quantity.The change in electrical quantity is detected to reflect the liquid level in the vessel.

3、Steel belt level meter

It is designed and made by utilizing the principle of mechanical balance.When the liquid level changes, the original mechanical equilibrium is disturbed by the buoyancy of the float, and a new equilibrium is achieved by the movement of the steel belt.The liquid level detection device (float) drives the steel belt to move according to the liquid level, and the displacement transmission system rotates the transmission pin through the movement of the steel belt, which in turn acts on the counter to display the liquid level.

4、Radar level meter

Radar level meters are measuring instruments based on the time travel principle. Radar waves travel at the speed of light, and the travel time can be converted into a level signal by the electronics.A high frequency pulse is emitted from the probe and propagated along the cable probe. When the pulse encounters the surface of the material, it is reflected back and received by the receiver inside the meter, and the distance signal is converted into a level signal.

5、Magnetostrictive liquid level meter

When the sensor of the magnetostrictive level meter works, the circuit part of the sensor will stimulate a pulse current on the waveguide wire, and the current will generate a pulse current magnetic field around the waveguide wire when it propagates along the waveguide wire.In the magnetostrictive liquid level meter sensor rod is equipped with a float, the float can move up and down along the measuring rod with the change of liquid level.Inside the float there is a set of permanent magnetic rings.When the magnetic field of the pulsed current meets the magnetic field of the magnetic rings generated by the float, the magnetic field around the float is altered so that the waveguide filament made of magnetostrictive material generates a torsional wave pulse at the position of the float, which travels back along the waveguide filament at a fixed speed and is detected by the detection mechanism.By measuring the time difference between the pulse current and the torsion wave, the position of the float, i.e. the liquid level, can be precisely determined.

6、Radio-frequency conduction liquid level meter

RF conductive material level meter consists of sensor and control instrument, the sensor can be installed on the top of the silo with rod, coaxial or cable type probe.The pulse card in the sensor can convert the level change into pulse signal and send it to the control instrument, which converts it into engineering quantity and displays it after arithmetic processing, thus realizing the continuous measurement of the level.

7, Tuning fork level meter

The working principle of tuning fork level controller is that a pair of piezoelectric crystals mounted on the tuning fork base makes the tuning fork vibrate at a certain resonance frequency.When the tuning fork is in contact with the measured medium, the frequency and amplitude of the tuning fork will change, and these changes will be detected, processed and converted into a switching signal by an intelligent circuit.

8. Glass plate level meter (glass tube level meter)

Glass plate liquid level meter is connected to the container through the flange to form a connector, through the glass plate can be directly read the height of the liquid level in the container.

9、Pressure level transmitter

Pressure level meter adopts hydrostatic measurement principle, when the level transmitter is put into a certain depth in the measured liquid, the sensor meets the pressure on the liquid surface at the same time, through the gas-conducting stainless steel will be the pressure of the liquid into the sensor's positive pressure chamber, and then the atmospheric pressure Po on the liquid surface is connected to the sensor's negative pressure chamber, in order to offset the sensor's back of the Po, so that the sensor measures the pressure as: ρ . g. H, through the measurement of pressureP , the liquid level depth can be obtained.

10、Capacitance liquid level meter

A capacitance level gauge measures the height of the liquid level by measuring the change in capacitance.It is a metal rod inserted into the liquid container, the metal rod as a capacitance of one pole, the container wall as the capacitance of the other pole.The medium between the two electrodes is the liquid and the gas above it.Due to the liquid dielectric constant ε1 and the liquid surface of the dielectric constant ε2 is different, for example: ε1> ε2, when the liquid level rises, capacitive level meter between the two electrodes of the total value of the dielectric constant increases and thus the capacitance increases.Conversely, when the liquid level falls, ε value decreases, the capacitance also decreases.Therefore, the capacitance level meter can measure the liquid level by the change of the electric capacity between the two electrodes.

11、Intelligent electric float level meter

Intelligent electric float level meter is designed according to Archimedes' law and magnetic coupling principle, the instrument can be used to measure liquid level, boundary level and density, responsible for the upper and lower limit level alarm signal output.

12、Float level meter

It is designed and made by utilizing the principle of mechanical balance.When the liquid level changes, the original mechanical equilibrium will reach a new equilibrium through the movement of the steel belt (rope) when the float is disturbed by buoyancy.The liquid level detection device (float) drives the steel belt (rope) to move according to the liquid level, and the displacement transmission system drives the on-site indication device through the movement of the steel belt (rope), which then shows the liquid level on the display device.

13、Float Level Transmitter

The float is submerged in the liquid inside the float chamber and is rigidly connected to the torsion tube system, which is subjected to a force that is the net value of the float's self-weight minus the buoyancy force applied to the float, and the torsion tube is twisted by a certain angle under the action of this combined force.Changes in the position, density or level of the liquid inside the float chamber cause a change in the buoyancy force on the float submerged in the liquid, which causes the angle of the torsion tube to change as well.The change is transmitted to the torsion tube rigidly connected to the sensor, so that the sensor output voltage changes, followed by electronic components to amplify and convert to 4 ~ 20mA current output.The float level transmitter uses a microcontroller with associated electronics to measure process variables, provide current output, drive the LCD display and provide HART communication capability.

14、Electrical contact liquid level meter

The electric contact water level meter is designed according to the different resistivity of water and vapor.The electrodes of the measuring cylinder have a low impedance to the cylinder in water.In it the impedance to the barrel is large.As the water level changes, the number of electrodes in the water produces a changeConverted into changes in resistance value.Transmit to the secondary instrument, so as to realize the water level display, alarm, protection interlock and other functions.

15、Magnetic sensitive two-color electronic liquid level meter

Magnetic electronic two-color level meter is made of high-quality stainless steel and imported electronic components, the display part adopts high brightness LED two-color light-emitting diode to form a column display, through the red and green change of LED light column, it can realize the alarm and control of liquid level upper and lower limits.

16、External liquid level meter

The External Level Gauge is an instrument that utilizes the sonar ranging principle and "micro-vibration analysis" technology to measure the liquid level from outside the vessel.Two compact ultrasonic sensors are mounted at the bottom of the tank and the other at the side wall of the tank to compensate for density variations.The signals from the external level sensors are transformed by a microprocessor and output to a local display or user control system.The height of the liquid in the tank and the volume of the liquid in the tank can be calculated .

17、Static pressure level meter

Hydrostatic level transmitter, the diffusion silicon oil-filled core encapsulated in a stainless steel shell, the front end of the protective cap to protect the sensor diaphragm, but also to enable the liquid smooth contact with the diaphragm, waterproof wires and hermetically sealed shell connected to the ventilation pipe in the cable and the outside world is connected to the internal structure of the design of the anti-dew condensation.

18、Ultrasonic liquid level meter

Ultrasonic liquid level meter/level meter is composed of a complete ultrasonic sensor and control circuit.Through the ultrasonic sensor launched by the ultrasonic wave reflected by the surface of the liquid, return to the time needed for calculation, through the temperature sensor on the ultrasonic transmission process of the temperature effect is corrected, converted into the liquid surface from the ultrasonic sensor distance, through the LCD output 4mA-20mADC analog signal, to achieve the field instrumentation to read remotely.

19、Differential Pressure Level Gauge (Double Flange Level Gauge)

Differential Pressure Level Transmitter is an electrical component that measures the difference between high and low pressure and then converts it into a current signal to be transmitted to the control room by the conversion part.Differential Pressure Level Transmitter is mainly used for liquid level measurement of closed pressure vessel.The size of the differential pressure also represents the size of the liquid level height.A differential pressure meter is used to measure the differential pressure between the gas and liquid phases to know the liquid level.