In the heating and air conditioning and gas engineering, often need to measure a variety of containers or equipment in the position of the interface between the two media, such as boiler packages in the vapor and liquid interface between the position of the reservoir in the depth of the liquid, the amount of liquid in the feed tank, etc., which is the liquid level detection.

Synopsis

Detecting liquid level means measuring the position of the interface between a gas and a liquid.The height between the liquid level and the zero reference point, i.e. the liquid level, is generally determined using the bottom surface of the equipment or container as or reference point.The purpose of detecting the liquid level is to measure the quantity of the substance as well as to monitor or control the process of continuous production in order to ensure that the production is safe, economical and smooth, so the detection of the liquid level is very important.

Liquid level is a variable that belongs to the category of mechanical displacement, so various methods of measuring length and distance can be used in principle by converting the amount of liquid level position as necessary.The unit of liquid level detection is m, cm, etc.

Hydrostatic Level Gauge

Hydrostatic level gauge is the use of the container with a certain height of the liquid on the bottom or side of a certain point to produce a certain pressure, measure the pressure of this point, or measure the pressure difference between the point and the reference point.Can then indirectly determine the height of the liquid level.Liquid level detection is the height of the liquid into the pressure or differential pressure measurement, and make the liquid level measurement is very simple, reliable, such as high-precision pressure gauge and electric differential pressure transmitter can be composed of automatic liquid level detection system.

Digital water level meter with electric contact

Electric contact digital water level meter is a simple and reliable new type of water level measurement instrument.It utilizes the difference in the electrical conductivity of furnace water and steam in the boiler ladle to measure the water level, which basically overcomes the influence of pressure changes in the ladle, especially in the process of starting and stopping the boiler, it can accurately display the water level in the ladle.It can realize long-distance, non-inertia rapid measurement.As it adopts digital display of water level value, thus it is easy to read, accurate and intuitively eye-catching.The electric contact digital water level meter consists of a water level sensor and a digital water level display.

An electric contact digital water level meter is a measurement system consisting of a water level measuring cylinder, an electrode and a display.The electrode is mounted on the water level measuring cylinder to form the electrode water level sensor.The core of the electrode and the water level measuring cylinder shell should have good insulation.As the steam in the industrial boiler ladle and the furnace water contains a lot of difference in the amount of conductive medium, so the difference in its conductive ability is also very large.Furnace water containing conductive medium is much more than steam, so the furnace water compared to steam, its conductive capacity is much larger.General industrial boiler saturated steam resistivity than saturated water to be several to thousands of times larger.And more than hundreds of times larger than the steam condensate, so that the electrode can be used to distinguish between steam and furnace water.As the conductivity of water is good, so the electrode immersed in water through the water and water level measurement cylinder shell constitutes a circuit, so that the corresponding display luminous, indicating the position of the water surface, while the electrode in the steam due to the resistivity of steam is very large, so the circuit does not work, then the corresponding display does not glow.So that the level of the water can be used to display the light bulb reflected, or by the transmitter into a voltage signal, to the digital display instrument.

Structure of electric contact water level sensor

The electrical contact water level sensor generally consists of a measuring cylinder housing, an electrical contact and an electrical contact holder.

The shell of the measuring cylinder is made of seamless steel tube, the length of which is decided according to the measuring range of water level.The core of the electrode of the electric contact sensor and the porcelain seal are welded together as one pole of the electrode; the fixing screw and the porcelain seal are welded together as the common grounding pole.The two are insulated with porcelain tube.The number of ports of the electric contact should meet the requirements of monitoring the boiler water level.

Electric contact digital water level indicator

The electric contact digital water level indicator consists of input conversion circuit, logic switch circuit, display control circuit, digital level indicator, alarm circuit, self-test circuit and power supply.

The function of the input conversion circuit is to convert the AC voltage signal output from the water level sensor or the AC voltage signal output from the self-test circuit for the analog water level into a DC voltage signal.

When working, the water level sensor or self-test circuit output reflects the water level of the AC voltage signal, sent to the input conversion circuit converted to DC high potential signal, and then input logic switching circuit and display control circuit, and finally by the digital tube to display the water level sensor or analog indication of the value of the water level, self-checking circuit is used to check the instrumentation circuitry whether the work is normal.When the water level reaches the high and low limits, the water level meter can also issue a light alarm.The limits of the high and low water level alarms are based on the fluctuation range of the boiler ladle water level.

Capacitance Level Gauge

Capacitance level juice is mainly includes measuring capacitance level sensor, multi-core shielded electric, cable front line and display instrument circuit four parts.

Measurement of non-conductive liquid capacitance sensor using sleeve-shaped structure, the inner electrode is made of metal rods, in its external set of a coaxial metal and its insulation of the external electrode for the outer brief.There are many small holes on the outer electrode so that the medium can pass through smoothly, and the inner and outer electrodes are fixed and insulated with insulators.If the liquid container is a metal cylinder, it is directly as the outer electrode.The capacitance sensor detects the level of the capacitance generated by the change in the amount of small values, direct measurement is difficult, so it needs to be amplified and converted through electronic circuits in order to make the display and remote transmission.

The measurement preamplifier consists of a capacitance measuring diode bridge, a power amplifier and a bi-directional limiter, etc., and is mounted in a junction box on top of the electrodes.The measurement front line is connected to the display instrument through a multi-core shielded cable.From the display instrument to the high-frequency square wave after shaping, power amplification and limiting to promote the measurement of capacitance two-plate tube bridge work, the bridge output DC current signal and through the cable into the display instrument DC amplifier.Display meter circuit consists of crystal oscillator, frequency divider, zero unit, DC amplifier and power supply.

A crystal oscillator is used to generate a high-frequency square wave, which is divided into various frequencies by a frequency divider for coarse adjustment of the meter's fullness.Zeroing unit by selecting the appropriate built-in capacitance, so that its ring diode bridge output a current to the DC amplifier, offset due to the existence of the starting capacitance so that the measurement of the front line does not level the current generated by the street, so that it outputs the indication for the purpose of zero, so as to achieve the purpose of zeroing.The DC amplifier will measure the DC signal sent from the front line and the output signal after comparing with the zeroing unit is amplified to a standard signal of 0-10mA for indication or remote transmission.

Capacitance level meter is suitable for a variety of non-conductive (or conductive) liquid level long-distance continuous measurement and indication, but also can be used with electric unit combination instrumentation, in order to realize the automatic control of liquid level.

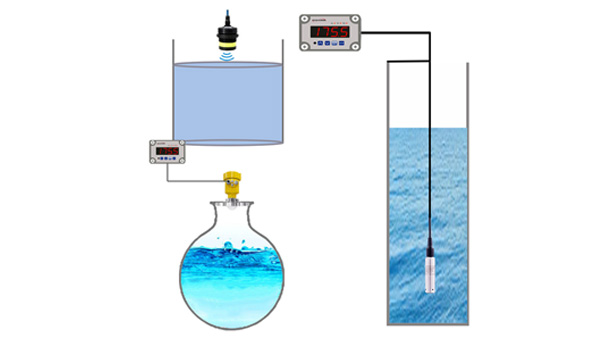

Ultrasonic level meter

Ultrasonic level meter is a liquid level meter that uses piezoelectric crystal transducer to transmit and receive ultrasonic waves and measure the liquid level according to certain acoustic characteristics of ultrasonic wave propagation in the medium.The ultrasonic transducer alternates as ultrasonic transmitter and receiver, or two transducers can be used as transmitter and receiver respectively, and it is liquid level detection sensor.Ultrasonic transducer is based on the piezoelectric crystal "piezoelectric effect" and "inverse piezoelectric effect" principle to realize the mutual conversion of electric energy and ultrasonic energy.

When an external force is applied to the end faces of a crystal, an electric charge appears on its two opposite faces and the polarity of the charge on the two end faces is reversed.If a wire is used to connect the electrodes of the two faces of the crystal there is a flow of electric current.When the external force disappears, the neutralized charges are immediately separated again, forming a current in the opposite direction to the original one.If an alternating external force is applied to the crystal ends, an alternating electric field is produced, which is the piezoelectric effect.Conversely, if the alternating voltage on the electrodes of the two end faces of the crystal, it will produce the inverse piezoelectric effect, that is, along the direction of the thickness of the crystal rest for the elongation and compression of the alternating changes in the direction of the mechanical vibration with the added alternating voltage at the same frequency, and to the surrounding medium to emit ultrasonic waves.

When using ultrasonic level meter for measurement, the ultrasonic transducer is placed at the bottom of the container (or over the liquid).When playing the role of the control clock of the main control polytunnel oscillator every square wave signal, it will stimulate the transducer to launch the sound pulse, and make the compound zero single steady sends out a signal, the counter will be zero again, but also began to adjustable oscillator issued by the time of the pulse counting, to the reception of the liquid and the reflection of the wave signal and immediately stop counting, and finally the sound pulse from the launch of the round-trip time of return of the counting of converted to the height of the liquid level to display it.