Products Description

According to different measurement principles, radar level gauges can be divided into two types. It is a radar level gauge that controls the liquid level, and its accuracy is generally about 10mm; the other is a radar level gauge, which is used for precise measurement and settlement, with an accuracy of 1mm. Structurally, it is divided into rod antenna, horn antenna and cable antenna, debugging, installing and using the analog signal output by the radar level gauge. The digital signal is superimposed on it by 4~20mADC to realize the compatibility of analog signal and digital signal, conforming to HART protocol. It can provide users with more attractive solutions, especially suitable for large fluctuations, condensation, suspension, viscous slurries, dirty media, and corrosive liquid level measurement. It has a continuous frequency self-calibration function to ensure stable measurement accuracy; it uses HART protocol for digital communication, and uses communication equipment or portable handheld devices to process liquid level variables; the output signal is an analog signal and a HART digital signal superimposed. Using the 4-20mAhar manual operator, the output signal can be divided into liquid level, calculated volume or standard volume; all configuration information and programs are stored in non-erasable memory. When the power is interrupted, all data can be restored; the frequency is continuously self-calibrated to ensure the accuracy of the level gauge.

The typical installation method of hydraulic radar for measuring rivers and reservoirs is as follows

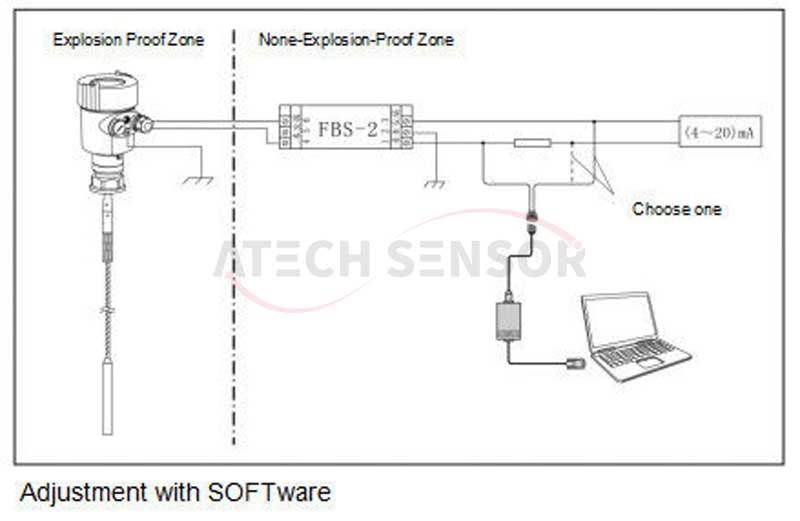

Explosion Proof Connection.

The intrinsic safety version sensors (Exia IIc T6) use Alu-die casting housing and filling Silicone rubber sealants internal structure aimed to prevent sparks resulted from circuit failure from leaking out. It is applicable for the continuous level measurement of flammable medium under Exia IIc T6.

A safety barrier FBS-2 must be used together with the intrinsic safety instrument. It is an associated device to this product for the power supply of this product. The main specification is intrinsic safety: Exia IIC, voltage of power supply: 24V DC±5%, short-circuit current: 135mA, operating current: 4...20mA.

All cables must be shielded. The max length is 500m for the cable from the barrier to the sensor. Stray capacitor≤0.1μF/Km, stray inductance 1mH/Km. Instrument must be connected to the ground potential. Any unapproved associated device is not allowed to be used.

Product Features

●High measurement accuracy, up to millimeter level;

● Not affected by the environment, can penetrate vacuum, haze, rain and snow, etc.;

● Not affected by the measured medium, can measure any liquid;

● No need to build a water level well, simple installation and maintenance;

● Low power consumption, can be powered by solar energy;

● Rich functions, can achieve continuous online acquisition, filtering and interference elimination, etc.

Product Specification

| Suitable for Medium: | Liquids, especially high temperature and pressure environment of liquid |

| Application: | Sealed cans, greater pressure liquid measurement |

| Explosion-proof Grade: | Exia IIC T6 Ga/Exd IIC T6 Gb |

| Measuring Range: | 15m |

| Antenna: | Single cable or single rod antenna |

| Accuracy: | ±10mm |

| Process Temperature: | (-200~400)℃ |

| Process pressure: | (-0.1~40)MPa |

| Signal output: | (4~20)mA/HART |

| The Scene Display: | Four LCD/Can be programmed |

| Power Source: | Two-wire (DC24V), Four-wire(DC24V/AC220V) |

| Shell: | Aluminum /Plastic |

| Connection: | Flange (optional) / Thread |

| Frequency: | 500MHz-1.8GHz |

Selection and Installation of Guided Wave Radar

1.All jars with agitation cannot be measured directly by using guided wave radar. Install the waveguide or bypass tube, the radar is installed inside the tube to measure and install a bracket

2. Guided wave radar can penetrate about 20cm of foam, thicker foam cannot Guaranteed effect

3. Guided wave radar is suitable for slightly crystalline working conditions. Enhanced resistance to crystallization or coagulation

Configuration of flange

1. HKD701 radar standard minimum matching flange is DN50,

2. Flat welding is compatible with DN40 flange,

3. Special type, can be matched with DN20 flange by extension sensor.

4. HKD701 is made of metal for the tank top and can be screwed.

Product Dimensions

Product Features

●High measurement accuracy, up to millimeter level;

● Not affected by the environment, can penetrate vacuum, haze, rain and snow, etc.;

● Not affected by the measured medium, can measure any liquid;

● No need to build a water level well, simple installation and maintenance;

● Low power consumption, can be powered by solar energy;

● Rich functions, can achieve continuous online acquisition, filtering and interference elimination, etc.

Product Dimensions

Product Specification

| Suitable for Medium: | Liquids, especially high temperature and pressure environment of liquid |

| Application: | Sealed cans, greater pressure liquid measurement |

| Explosion-proof Grade: | Exia IIC T6 Ga/Exd IIC T6 Gb |

| Measuring Range: | 15m |

| Antenna: | Single cable or single rod antenna |

| Accuracy: | ±10mm |

| Process Temperature: | (-200~400)℃ |

| Process pressure: | (-0.1~40)MPa |

| Signal output: | (4~20)mA/HART |

| The Scene Display: | Four LCD/Can be programmed |

| Power Source: | Two-wire (DC24V), Four-wire(DC24V/AC220V) |

| Shell: | Aluminum /Plastic |

| Connection: | Flange (optional) / Thread |

| Frequency: | 500MHz-1.8GHz |

Selection and Installation of Guided Wave Radar

1.All jars with agitation cannot be measured directly by using guided wave radar. Install the waveguide or bypass tube, the radar is installed inside the tube to measure and install a bracket

2. Guided wave radar can penetrate about 20cm of foam, thicker foam cannot Guaranteed effect

3. Guided wave radar is suitable for slightly crystalline working conditions. Enhanced resistance to crystallization or coagulation

Configuration of flange

1. HKD701 radar standard minimum matching flange is DN50,

2. Flat welding is compatible with DN40 flange,

3. Special type, can be matched with DN20 flange by extension sensor.

4. HKD701 is made of metal for the tank top and can be screwed.