Products Description

The immersion liquid level sensor is a pressure sensor for measuring liquid level. It is based on the principle that the static pressure of the measured liquid is proportional to the height of the liquid. It uses an isolated diffused silicon sensitive element or a ceramic capacitor pressure sensitive sensor to convert the static pressure into an electrical signal, which is then converted into a standard electrical signal after temperature compensation and linear correction. It is generally suitable for liquid level measurement of various media in systems and industries such as petrochemicals, metallurgy, electric power, pharmaceuticals, water supply and drainage, and environmental protection.

Product Features

●High-performance ceramic sensor core, equipped with advanced chip dedicated to highly integrated bridge pressure sensor for signal conditioning.

●Digital temperature compensation and nonlinear correction

● Multi-channel signal output, equipped with breathable cable: perfect solution to gauge pressure error caused by disconnection of sensor from atmosphere.

●High sensitivity, high precision, high stability

● Full temperature range temperature compensation, good electrical performance, good long-term stability

●A protective cover is installed on the liquid inlet for easy cleaning, which can effectively prevent sand, gravel and sedimentation.

●Customizable according to customer needs, OEM/laser marking, cost-effective, one-year warranty

Product Specification

Measuring range: | 0-200 M | |||

Overload pressure: | 200%FS | |||

Comprehensive accuracy: | ±1% | ±0.5% | ±0.2% | ±0.1 |

Temperature drift: | ±0.03%/ºC | |||

Temperature compensation range: | -10~70ºC | |||

Long-term stability: | ±0.3%FS/year | |||

Working temperature: | -40~85ºC | |||

Storage temperature: | -40~125ºC | |||

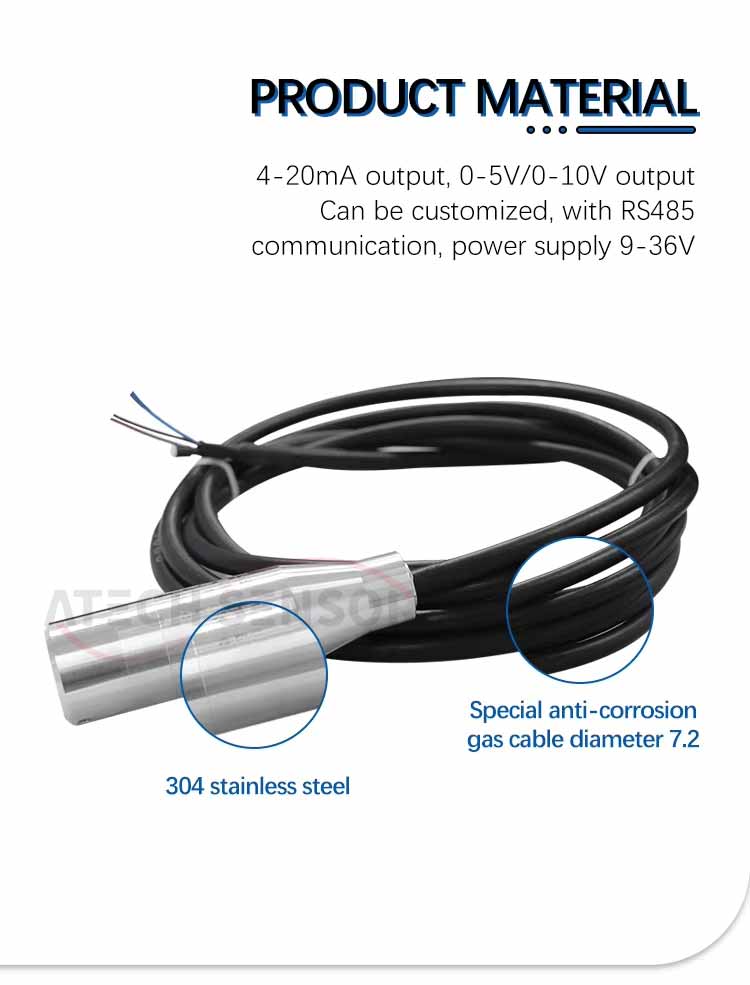

Output signal: | absolute value 0-10V | IIC | 4-20mA | RS485 |

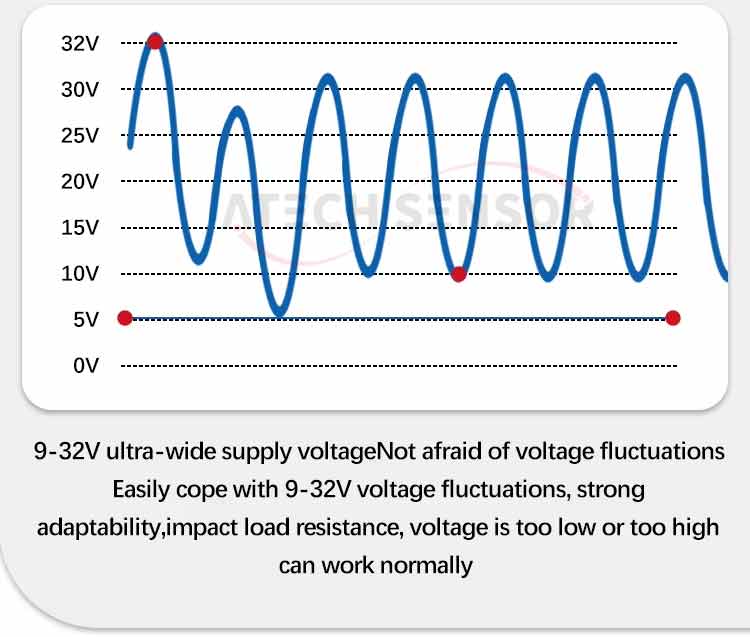

Supply voltage (V): | 10-36 | 3.0-5.5 | 3.0-5.5 | 10-36 |

Load (Ω): | >10K | >10K | ≤50(U-10) | |

Protection level: | IP68 | |||

Media adaptability: | various non-corrosive fluids | |||

Vibration: | 10gRMS, (20~2000)Hz | |||

Shock: | 100g, 11ms | |||

Insulation: | greater than 100MΩ @250VDC | |||

Response time: | less than 1ms | |||

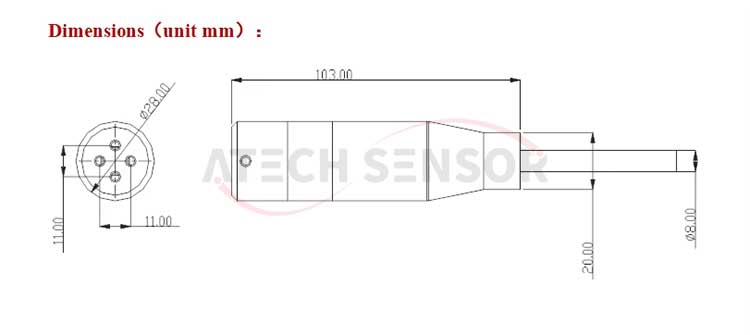

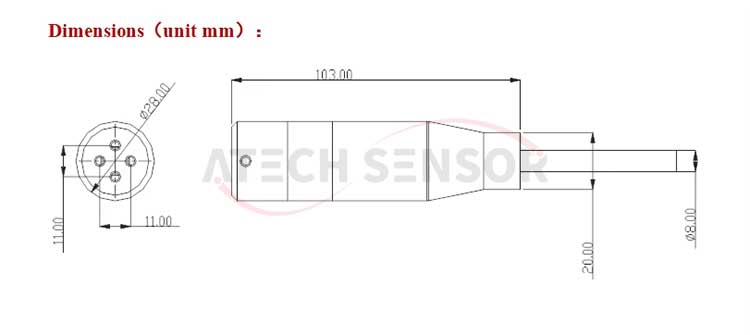

Product Dimensions

Product Features

●High-performance ceramic sensor core, equipped with advanced chip dedicated to highly integrated bridge pressure sensor for signal conditioning.

●Digital temperature compensation and nonlinear correction

● Multi-channel signal output, equipped with breathable cable: perfect solution to gauge pressure error caused by disconnection of sensor from atmosphere.

●High sensitivity, high precision, high stability

● Full temperature range temperature compensation, good electrical performance, good long-term stability

●A protective cover is installed on the liquid inlet for easy cleaning, which can effectively prevent sand, gravel and sedimentation.

●Customizable according to customer needs, OEM/laser marking, cost-effective, one-year warranty

Product Dimensions

Product Specification

Measuring range: | 0-200 M | |||

Overload pressure: | 200%FS | |||

Comprehensive accuracy: | ±1% | ±0.5% | ±0.2% | ±0.1 |

Temperature drift: | ±0.03%/ºC | |||

Temperature compensation range: | -10~70ºC | |||

Long-term stability: | ±0.3%FS/year | |||

Working temperature: | -40~85ºC | |||

Storage temperature: | -40~125ºC | |||

Output signal: | absolute value 0-10V | IIC | 4-20mA | RS485 |

Supply voltage (V): | 10-36 | 3.0-5.5 | 3.0-5.5 | 10-36 |

Load (Ω): | >10K | >10K | ≤50(U-10) | |

Protection level: | IP68 | |||

Media adaptability: | various non-corrosive fluids | |||

Vibration: | 10gRMS, (20~2000)Hz | |||

Shock: | 100g, 11ms | |||

Insulation: | greater than 100MΩ @250VDC | |||

Response time: | less than 1ms | |||