A pressure sensor is a device that measures the pressure exerted by a fluid (liquid or gas) and converts it into an electrical signal that can be processed or displayed. Pressure, in this context, refers to the force applied per unit area, and the sensor’s role is to detect this force and relay it in a form that can be understood and utilized by machines or monitoring systems.

Pressure sensors typically consist of a diaphragm or membrane that deforms under pressure. This deformation is measured by various technologies such as strain gauges, piezoelectric materials, or capacitive sensing. The change in deformation is converted into a corresponding electrical signal, which is then interpreted to give a precise pressure reading.

These sensors are used across many industries, from monitoring tire pressure in cars to measuring blood pressure in medical devices, and they come in various forms to meet specific requirements, including absolute, gauge, and differential pressure sensors.

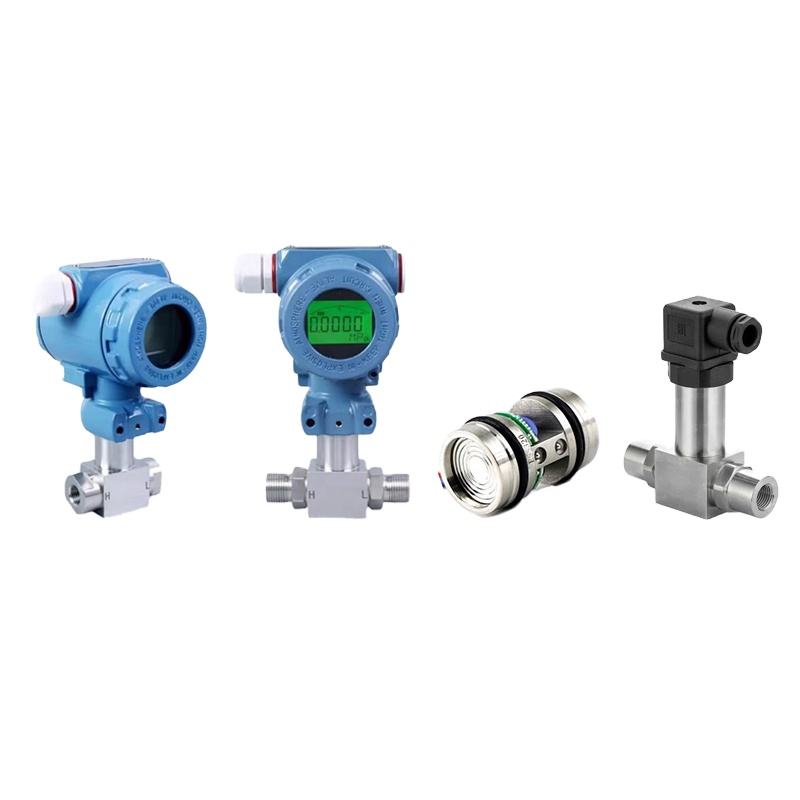

Types of Pressure Sensors

Pressure sensors come in various types, each designed to measure pressure in specific ways based on the needs of different applications. Below are the main types of pressure sensors:

1. Absolute Pressure Sensors

• Application: Often used in scientific research, weather monitoring, and industrial processes where precise pressure measurements are critical.

• Example: Barometric pressure sensors used in meteorology.

2. Gauge Pressure Sensors

• Application: Commonly used in automotive applications such as tire pressure monitoring or measuring fluid pressure in tanks and pipelines.

• Example: Tire pressure gauges.

3. Differential Pressure Sensors

• Application: Widely used in flow rate measurements, ventilation systems, and filtration systems to monitor pressure drop across filters.

• Example: HVAC systems where differential pressure is measured across airflow channels.

4. Sealed Pressure Sensors

• Application: Used where the sensor needs to operate in extreme environmental conditions, such as in marine or aerospace applications.

• Example: Pressure sensors in submarines or airplanes.

5. Vacuum Pressure Sensors

• Application: Used in industries where vacuum environments are required, such as semiconductor manufacturing, space simulations, or vacuum packing.

• Example: Sensors in vacuum pumps used in laboratories.

6. Hydrostatic Pressure Sensors

• Application: Commonly used for liquid level measurement in tanks, reservoirs, and water systems.

• Example: Sensors used in water towers to monitor fluid levels.

7. Piezoresistive Pressure Sensors

• Application: Found in a wide range of consumer electronics, automotive systems, and industrial machinery.

• Example: Pressure transducers in hydraulic systems.

8. Capacitive Pressure Sensors

• Application: Used in environments requiring sensitive pressure measurement, such as in medical equipment or sensitive laboratory instruments.

• Example: Blood pressure monitors in medical devices.

Each type of pressure sensor is designed for specific applications, providing accurate and reliable pressure measurements depending on the conditions and requirements of the task.

Pressure sensors operate by converting physical pressure into an electrical signal that can be measured and analyzed. The process involves a few key components and mechanisms, depending on the sensor type and the technology it uses. Below is an overview of how a typical pressure sensor works:

1. Sensing Element

2. Detection of Deformation

Capacitive Sensing: Some pressure sensors measure the change in capacitance between two plates. As the diaphragm moves in response to pressure, the distance between the plates changes, which alters the capacitance. This change is measured and converted into an electrical signal.

Piezoelectric Sensors: In these sensors, pressure is measured using materials that generate an electrical charge when subjected to mechanical stress. When pressure is applied to a piezoelectric material, it generates a voltage signal proportional to the pressure.

3. Signal Conversion

4. Signal Amplification and Conditioning

5. Output

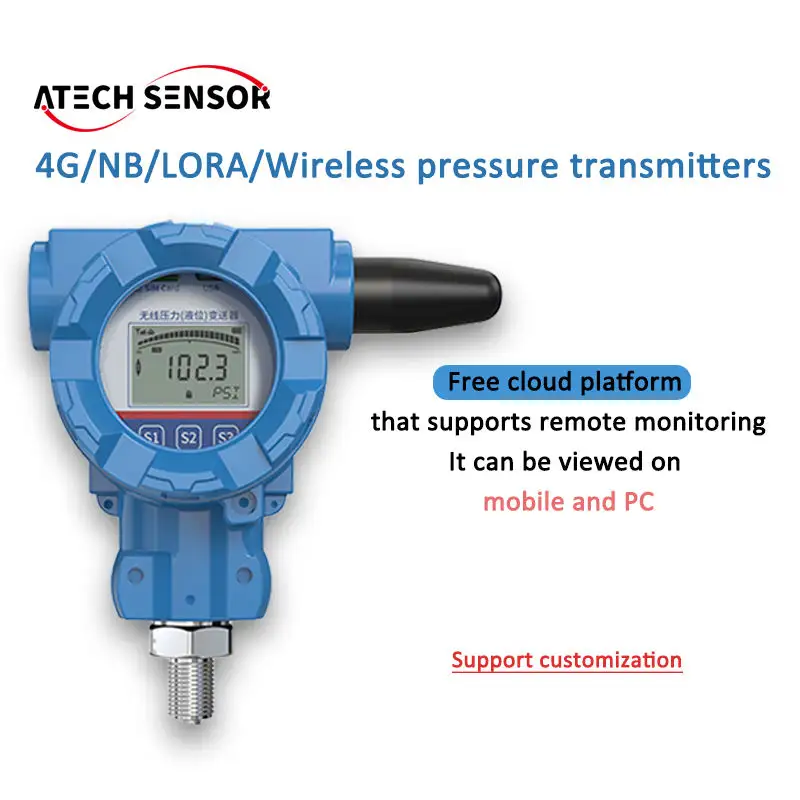

Common Applications of Pressure Sensors

1. Automotive Industry

Engine and Fuel Systems: Pressure sensors monitor fuel pressure, oil pressure, and boost pressure in turbocharged engines to ensure proper engine function and prevent damage.

Brake Systems: In advanced braking systems, pressure sensors help monitor hydraulic fluid pressure to assist with stability control and anti-lock braking systems (ABS).

2. Medical Industry

Respiratory Devices: Pressure sensors are integral to devices like ventilators and CPAP machines, where they regulate and monitor air pressure delivered to patients.

Infusion Pumps: These pumps rely on pressure sensors to maintain and control the flow of fluids into a patient’s body at precise rates.

3. Industrial Applications

Hydraulic Systems: Pressure sensors are critical in hydraulic systems used in heavy machinery, where they monitor pressure to maintain proper force and system efficiency.

Boilers and HVAC Systems: Pressure sensors regulate pressure in heating, ventilation, and air conditioning (HVAC) systems, as well as in industrial boilers to maintain optimal working conditions.

4. Consumer Electronics

Appliances: Pressure sensors are used in household appliances like washing machines and dishwashers to control water levels and ensure proper operation.

5. Aerospace and Aviation

Fuel Systems: Sensors are used to monitor fuel tank pressure and prevent dangerous over-pressurization or leaks during flight.

6. Oil and Gas Industry

Wellhead Monitoring: Pressure sensors are deployed in oil wells to measure the pressure of fluids in reservoirs, which is critical for efficient extraction processes.

7. Environmental Monitoring

Water Treatment Plants: Pressure sensors are used to monitor and control the pressure in water filtration and distribution systems to ensure smooth and efficient operations.

8. Marine Applications

Ballast Systems: Pressure sensors regulate the pressure in ballast tanks to control a vessel’s buoyancy.

9. Food and Beverage Industry

Carbonation Control: Pressure sensors are used to regulate the pressure in beverage carbonation processes, maintaining the desired levels of CO₂ in drinks.

10. Manufacturing

Leak Detection: Pressure sensors are employed in quality control processes to detect leaks in sealed products or components, ensuring product integrity.

Pressure sensors provide essential real-time data for control systems, improve safety, and optimize efficiency in a wide range of applications across industries.

Conclusion