What are Level Sensors?

Level sensors are components used in fluid control systems to determine the level of a tank or container. They can determine the levels of different types of free-flowing media such as liquids, powdered solids, and granular solids. They provide an electrical signal which automatically communicates when connected control valves should be opened or closed.

Depending on the specific level sensor, this could be either an output proportional to the level, or an output programmed to be given at a pre-set level or value.

Level sensors play a key role in fluid control systems. Having an accurate understanding of the current position, level, and displacement of a substance is imperative in a wide range of applications and environments, meaning that the importance of the level sensor should not be overlooked.

How Do Level Sensors Work?

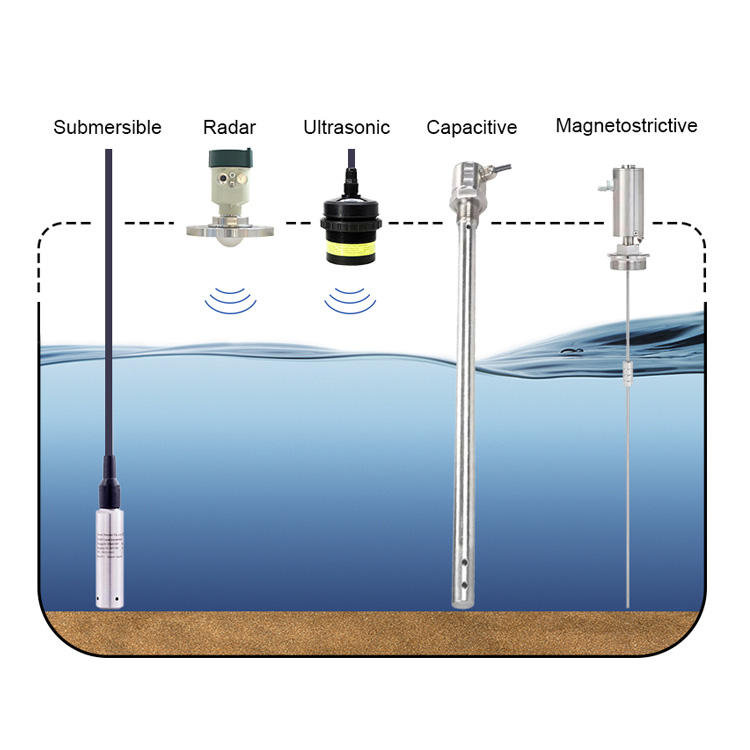

There are multiple types of level sensors, and each type uses a different method of gauging the level of media within the tank or container. This means that varying types of level sensors work in different ways, using distinct technologies and processes to complete their measurements.

• Optical Level Sensors – visible, laser, or infrared light

• Capacitive Level Sensors – non-contact sensing fields• Conductive Level Sensors – electrical contact outputs

• Vibrating Level Sensors – high-frequency vibrations

• Ultrasonic Level Sensors – ultrasonic pulses

• Microwave Level Sensors – electromagnetic energy

Types of Level Sensors

These factors include:

• What substance will be measured• Where the sensor will be used

• What position the sensor needs to be mounted in

Some of the most common types of level sensors are explored in greater detail in the sections below.

1.Optical Level Sensors

Beams of light are generated towards the surface of the substance. The sensor then works by recording instances of the light reflecting or refracting off the surface, which is achieved using one or more photocells. The response is almost instantaneous and accuracy levels are high with this type of sensor.

2.Capacitive Level Sensors

This type of level sensor is non-contact, meaning that they use sensing fields to read the level of the substance within the container. Capacitive level sensors are advantageous as they offer highly accurate sensing even with a heavy build-up of residue on the sensor.

3.Conductive and Resistive Level Sensors

Highly accurate and precise, conductive sensors are often used by professionals. This type of level sensor is used for measuring liquids and typical applications could include reservoirs, tanks, ponds, and sumps, as well as pharmaceuticals.

4.Vibrating and Tuning Fork Level Sensors

In addition to their indication uses, these sensors can also be used as overfill protection devices. Vibrating level sensors are primarily used to determine liquid levels, but they are also suitable for use with granulated and powdered bulk solids.

5.Ultrasonic Level Sensors

These sensors work by generating ultrasonic pulses, which reflect off the surface of the liquid being measured. To determine the level of the liquid, the sensor then calculates the time taken by the ultrasonic pulse to travel to the surface and back to the sensor. Although ultrasonic level sensors are highly accurate in practice, in reality, this is not always the case as the sensor’s response can be influenced by several external factors such as pressure, temperature, turbulence, and moisture levels.

6.Microwave and Radar Level Sensors

These sensors are typically used with metal and conductive water, as the media must have high conductive properties for the electromagnetic energy to reflect efficiently. These sensors can also be used at different frequencies for different applications and levels of accuracy.

Level Sensor Uses and Applications

Many processes which involve media in tanks or containers find the use of level sensors advantageous. These sensors can manage and monitor flow rate, provide accurate data, and be incorporated into larger fluid control systems. Their uses are myriad; just a few examples include media level sensing, detecting leaks, acting as an alarm system, providing overfill shutoff, and regulating media interface between multiple levels or substances.

Level sensors are used in many industrial applications, including industries as diverse as the following:

• Food and beverage

• Pharmaceuticals• Medicine

• Energy management

• Manufacturing

• Chemicals

• Marine environments