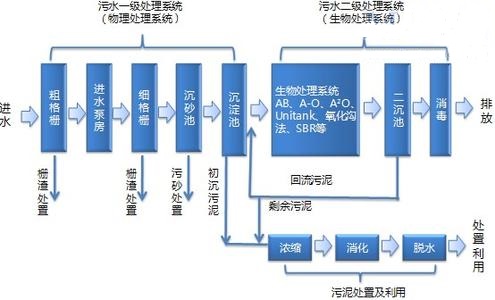

With the rapid development of our country's economy and the increase of industrialisation, the pollution of water resources is also intensifying, especially the increase in the discharge of urban sewage and industrial sewage, which has led to increasingly serious water pollution. The state attaches more and more importance to the protection of water resources, and has increased the treatment of urban sewage and industrial sewage, which puts forward higher requirements for achieving the best effect of various sewage treatment processes, the normal operation of treatment equipment, and the accurate monitoring of water quality and quantity of sewage treatment, which puts forward new requirements for the design and application of automatic instruments in sewage treatment.

In the process of modern sewage treatment, no matter what process is adopted, there are a large number of parameters that need to be detected, so at present, large-scale domestic sewage treatment plants or process sewage treatment plants are generally equipped with automatic instruments such as liquid level, liquid level difference, flow rate, pressure, pH, temperature, dissolved oxygen, sludge concentration, redox potential, sludge interface, online BOD, online COD, online ammonia nitrogen, online total phosphorus, etc.

Automatic control instrument application scheme

1.Commonly used instruments for sewage treatment

Automation instruments in sewage treatment are mainly divided into thermal instruments and composition analysis instruments. Thermal instruments mainly include temperature, pressure, liquid level, flow rate and other physical quantity detection instruments, and thermal instruments are generally composed of measuring elements (sensors), intermediate transmission parts and display parts (including conversion into other signals). Component analysis instruments are often called water quality analysis instruments in the sewage treatment process, such as dissolved oxygen meters, online BOD meters, online COD meters, etc. The main characteristics of this part of the instrument are strong specificity and diversified forms, but the scope of application of each component analyser is often limited to a certain medium composition analysis.

2.Temperature gauge

To ensure its normal and effective reaction during anaerobic digestion, the temperature of the medium needs to be maintained within a specific range; therefore, it is essential to set temperature detection points. The typical thermal sensitive element usually designed is the platinum thermal resistor (PT100, PT1000). Since the thermal resistor signal requires a dedicated thermal resistor module compatible with the automatic control system, and there are not many temperature monitoring points in the water treatment process, it is advisable to consider using a temperature transmitter in the instrument design to convert the thermal resistor signal into a 4-20mA signal, thereby allowing it to connect to a standard analog module.

3.Pressure transmitter

If the pressure transmitter needs to be set up, the intelligent pressure transmitter with very wide application and mature technology is mostly selected, so as to facilitate the range setting, zeroing and other operations of the pressure transmitter by cooperating with the hand operator. In the sludge treatment process in the later stage of sewage treatment, some plate and frame filter presses will also use pressure transmitters.

4.Flowmeter

Relatively speaking, flow meters are a very important type of instrument in sewage treatment. The amount of inlet and outlet water, the amount of sludge flowing back, the amount of aeration and the gas production of the digester in the sewage treatment plant are all flow parameters that must be measured for process production. In addition, in order to assess and analyse the economic effect of the operation of the sewage treatment plant, it is also necessary to rely on flow measurement instruments to provide necessary data. In the flow measurement instruments of sewage treatment plants, the most widely used are electromagnetic flow meters, ultrasonic flow meters, thermal gas mass flow meters and open channel flow meters.

5.Electromagnetic flowmeter

An electromagnetic flowmeter is a tachymeter flowmeter, which is suitable for measuring the volume flow rate of conductive liquids. Electromagnetic flowmeters are mainly composed of transmitters and converters. After the flow rate of the measured medium is converted into an induced potential by the transmitter, the induced potential signal is converted into a current signal as an output by the converter, to record the distant indication or as a control signal. The electromagnetic flowmeter has no fixed or movable throttling parts in the measurement channel, no pressure loss to the fluid, and its output characteristics are independent of the density, viscosity and flow condition of the measured liquid, making it suitable for measuring the flow rate of fluids with solid particles in sewage treatment. At the same time, the installation of the electromagnetic flowmeter does not have excessively high requirements for the straight pipe section, which is usually 5D at the front and 3D at the back (D being the inner diameter of the selected instrument). It is precisely because of these characteristics of the electromagnetic flowmeter that it is widely used in sewage treatment. Electromagnetic flowmeters can be considered for measurement on the inlet and outlet pipelines and sludge pipelines of sewage treatment plants. It should be noted that electromagnetic flowmeters have requirements for measuring the conductivity and flow rate of liquids, which need to be considered with special attention during design.

6.Ultrasonic flow meter

According to its installation form, ultrasonic flowmeters are generally divided into clamp-on type, pipe section type, and insertion type. According to their detection method, they can be divided into different types of ultrasonic flowmeters such as propagation speed difference method, Doppler method, beam offset method, noise method, and related methods. The pipeline clamp-on ultrasonic flowmeter can be installed without disconnecting the pipeline (unlike the electromagnetic flowmeter), and it does not require the installation of bypass pipelines and valves. The measuring pipeline diameter can reach several metres, allowing for easy maintenance, and can be used for flow measurement without any impact on the fluid. Thus, it is also more commonly used in flow measurement of large-diameter inlet and outlet pipelines in sewage treatment. In the design and application of ultrasonic flowmeters, special attention should be paid to choosing the appropriate installation position. The selected installation pipe should have good roundness, a smooth inner surface, and uniform wall thickness. The installation pipe section should avoid interference and eddy currents, as these have a significant impact on measurement accuracy, and the instrument should not be installed near the water pump and frequency converter, where there is a strong magnetic field and vibration interference. At the same time, it should also meet the corresponding requirements of the straight pipe section (10 times the pipe diameter upstream, 5 times the pipe diameter downstream).

7.Thermal gas mass flow meter

A gas flow measurement system with high accuracy and good stability plays a positive role in saving electrical energy and reducing operating costs for the blast aeration system. For the measurement of aeration in sewage treatment, thermal gas mass flow meters are mostly selected, segment hot gas mass flow meters are used for small pipes, and plug-in thermal gas mass flow meters are used for large diameters. The plug-in hot gas mass flow meter with ball valve support can be disassembled and maintained under pressure without affecting the operation of the fan and compressor. The differential pressure flow meter can also be selected for the measurement of sewage tank aeration, but because the differential pressure signal of the differential pressure flow meter is relatively small (about a few mmH2O to dozens of mmH2O), some measures need to be taken to ensure that the requirements of the front and rear straight pipe sections are met, such as gradually shrinking the pipe, increasing the flow rate, and increasing the differential pressure signal. In addition, it is necessary to select an appropriate differential pressure transmitter for accurate measurement, and it is recommended to use a high-precision (0.5%) differential pressure transmitter. When measuring gas flow, temperature and pressure compensation is required. When the temperature and pressure in the process pipeline do not change much, fixed temperature and pressure values can also be used to compensate for the measurement accuracy. Compared with thermal gas mass flow meters, differential pressure flow meters have higher cost and high maintenance costs, and are not cost-effective.

8.Nullah ultrasonic flow meter

Open channel ultrasonic flow meter is a widely used flow meter in sewage treatment plants, suitable for the occasion where the water inlet and outlet are in the form of open channels rather than pipes in the process flow. Nullah basher troughs, triangular weirs, trapezoidal troughs, rectangular troughs, etc. are commonly used in sewage plants. The selection of open channel flowmeter not only has high requirements for the accuracy, performance and stability of the instrument, but also has very high requirements for the production accuracy of different open channel specific weir grooves. Because no matter which weir trough is used, the size of the final flow Q is determined by the height h of the water level. Its function relationship is Q=F(h).

9.Physical (liquid) level meter

The level detection instrument is divided into liquid level detection instrument and material level detection instrument according to the measured medium, and the liquid level detection instrument is more commonly used in sewage treatment, and ultrasonic level gauges, immersion level gauges, magnetic flap level gauges, float level switches, etc. will be used in the process.

10.Ultrasonic level gauge/level difference meter

Ultrasonic level gauges have no mechanical moving parts, are highly reliable, easy and convenient to install, allow for non-contact measurement, and are not affected by the viscosity and density of liquids. Consequently, they are primarily used for measuring liquid levels in medical tanks, sludge drainage pools, and so on. The sensor of an ultrasonic level gauge consists of a pair of transmitting and receiving transducers. The transmitting transducer emits ultrasonic pulses towards the liquid surface, and the ultrasonic pulses are reflected back from the liquid surface to be received by the receiving transducer. The distance between the sensor and the liquid level can be determined based on the time from transmission to reception, which can then be converted into liquid level. Based on the non-contact measurement principle of the ultrasonic level gauge, it is theoretically suitable for measuring liquid levels in the sewage treatment process. However, in practical applications, it is influenced by various factors such as installation position, temperature, pressure, humidity, and foam and surges on the surface of the measured medium. According to the characteristics of ultrasound, the lower the frequency, the longer the transmission distance, though this results in poorer directivity of the sound wave; conversely, a higher frequency offers better directivity but a shorter transmission distance. Currently, ultrasonic level gauges have a measurement range from 0.5 metres to tens of metres. Ultrasonic level difference meters are used to measure the difference in liquid level or material level between two different containers. The most common application is at the water inlet of sewage treatment plants, where the water level before and after the coarse and fine grilles is measured to calculate the height of the water level difference, which is then used to activate the back-fishing decontamination machine to remove waste.

11.Drop-in level gauge

The immersion (static pressure) level gauge measures liquid levels based on the principle that static pressure is proportional to liquid height. The sensor uses imported American high-level dry ceramic capacitive sensors or temperature-compensated and isolated diaphragm-type silicon pressure sensors, with a dedicated microprocessing circuit. It adopts advanced European design concepts, with various structural forms, materials, and transmitter types, offering wide adaptability.

12.Magnetic flap level gauge

The magnetic flap plate (column) level gauge is a magnetic float driven two-colour magnetic plate (column) to indicate the liquid level, which can be used for the detection of medium level in various acid-alkali storage tanks. It compensates for the shortcomings of unclear and fragile glass plate (tube) level gauges, is not affected by drastic changes in high and low temperatures, does not require the combination of multiple sets of level gauges, and provides reliable safety. There are no blind spots in the entire measurement process, the display is eye-catching, the readings are intuitive, and the measurement range is large. In particular, the on-site indication part excels in high temperature, high pressure, high viscosity, toxic and harmful, and highly corrosive media because it does not come into direct contact with the liquid medium. It has higher reliability, safety, advancement, and applicability than traditional glass plate (tube) level gauges.

13.Slurry Water Interface Meter (Boundary Gauge)

The ultrasonic slurry interface meter uses the reliable ultrasonic echo detection principle to calculate the time when the ultrasonic wave returns to the probe, and the height and thickness of the sludge layer can be calculated. Effectively grasp the sludge sedimentation characteristics and accurately control the return flow of sludge. Allows operators to make real-time evaluations of optimising sludge circulation, compensating for daily fluctuations in wastewater, correcting abnormal state values, and monitoring separation layers in the pre-concentration tank.

In addition, the process does not require continuous detection, but only needs to alarm or interlock equipment operation. The liquid level in the pool, live liquid tank and other equipment can be detected by a liquid level switch, so as to control the investment in instrumentation equipment.

14.Analytical instrumentation

In the sewage treatment process, there are many important parameters that reflect water quality, such as: dissolved oxygen (DO), pH, sludge concentration, turbidity, SS suspended solids, etc. Online testing of these parameters can help understand and grasp the situation of sewage treatment in real time, and automatically control and adjust the operation of processes and equipment according to these parameters to ensure the normal operation of sewage treatment and meet discharge standards. With the development of automatic instrument measurement technology and other fields, more and more water quality analysis instruments are gradually applied to sewage treatment.

15.Dissolved oxygen meter

An important condition for the survival of microorganisms in water is that there is a certain amount of oxygen dissolved in the water, which is called dissolved oxygen (DO). When the water contains reducing pollutants, the amount of DO will decrease, and when the DO is below 4mg/l, it will be difficult for organisms in the water to survive. Therefore, dissolved oxygen is one of the important indicators of water quality monitoring. The oxygen content in the water can fully show the degree of water self-purification and the amount of sewage that can flow into the water. For biological treatment, it is more necessary to understand the oxygen content in the aeration tank, and control the oxygen supply of the blower to the aeration tank according to the oxygen signal. The dissolved oxygen meter is mainly composed of two parts: sensor and transmitter. Dissolved oxygen sensors in the sewage industry mostly use fluorescence to measure dissolved oxygen, the principle being that blue light shines on the fluorescent layer, the fluorescent substances are excited to emit red light, and the oxygen concentration is inversely proportional to the time when the fluorescent substances return to the ground state. This method is used to measure dissolved oxygen, no oxygen consumption will be generated during measurement, stable data, reliable performance, no interference, and simple installation and correction.

16.pH meter

The purpose of configuring pH meters at the inlet and outlet of the sewage is to facilitate the process personnel to take corresponding control and adjustment measures for the influent water quality to meet the requirements of subsequent treatment. The purpose of setting up a pH meter at the outlet is to reflect the effect of treatment and facilitate the supervision of the operation status of the sewage plant by the plant department and government departments. The basic working principle of the pH meter is to measure the pH of the solution by potentiometric method, and there is a fixed functional relationship between the potential difference between the measuring electrode of the solution to be measured and the reference electrode with a constant potential and the pH value of the solution, ensuring that the pH value is obtained by measuring the potential.

17.Sludge (suspended solids) concentration meter

The concentration of sludge is also one of the important parameters that need to be detected in the sewage treatment process. Sludge concentration meters are generally used in sludge treatment sections, mostly sinking safety meters in the tank, and can also be used for pipeline installation. On the one hand, it can improve the efficiency of sludge dewatering equipment (using plate and frame filter press), save energy consumption, and make the dehydrated sludge products drier and easier to transport. On the other hand, it can monitor and control the backflow or discharge of sludge. At present, the sludge concentration meter by optical method is commonly used.

18.Residual chlorine meter

The residual chlorine meter adopts the advanced constant voltage principle to measure residual chlorine in water bodies. This method uses the application of a stable potential between the polarized electrode and the reference electrode, under which different components produce different current intensities. The meter calculates the concentration of the measured component through the acquisition and analysis of the current signal. The residual chlorine electrode has a simple structure, is easy to clean and replace, and there is no need to replace the diaphragm and reagent during the use of the electrode, and the maintenance is simple, ensuring the stability, reliability and accuracy of the instrument for long-term operation.