The capacitive oil level sensor is a liquid level sensor based on the radio frequency capacitance measurement principle. It can be installed in various occasions to accurately measure the oil level of gasoline, diesel, hydraulic oil and other weakly corrosive liquids. The length can be customized according to customer requirements. It can output 4~20mA, 0~5V standard signals, as well as RS232 and RS485 communication signals. It can be used with satellite positioning monitoring systems, car modification factories, etc.

1.Features

Wide range of measurement media

It is not only suitable for measuring the level of various oils such as gasoline, diesel, kerosene, hydraulic oil, biodiesel, etc., but also suitable for measuring the level of liquids such as various chemical reagents and beer;

Various installation methods are available

Can support standard 5-hole flange installation, or threaded installation M20*1.5, or can be customized;

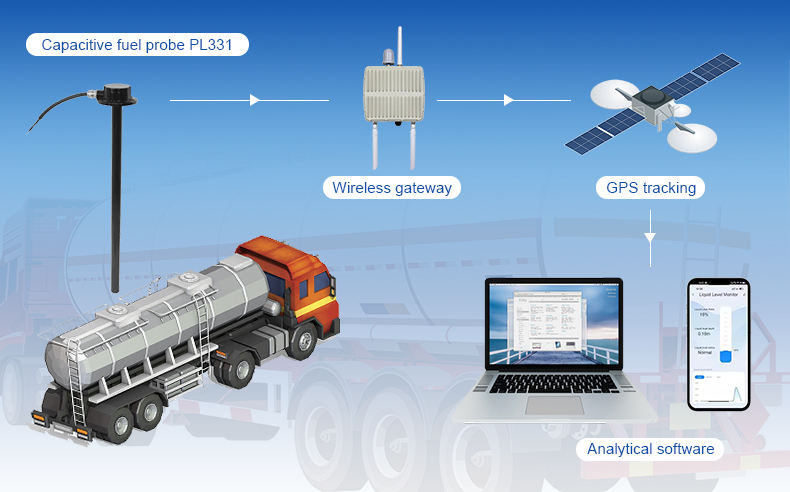

Adaptable to GPS

It can be adapted to GPS to realize real-time monitoring of oil level, and the data can be uploaded to the back-end software system;

Self-calibration function

Automatic calibration of sensors can be achieved without manual intervention or calibrator;

A variety of output signals are available

Can handle 4~20mA, 03.3V, 0-5V, RS485, RS232 and other signals;

2.capacitance oil level sensor Working principle

Capacitive Oil Level Sensor is based on the capacitance principle and uses the capacitance change in the medium to determine the level of the liquid.

First, capacitance is a common parameter in electronic components, which represents the ability to store charge between two conductors. The size of the capacitance depends on the distance between the two conductors and the nature of the medium. When the distance between two conductors is smaller, the capacitance is larger. Capacitance decreases as distance increases or the relative permittivity of the medium decreases.

Capacitive Oil Level Sensor uses liquid as a medium to change the capacitance value between two conductors. Normally, the dielectric constant of a liquid is much greater than that of air, so the liquid will cause a large capacitance change between the two conductors.

Capacitive Oil Level Sensor usually consists of two electrodes, one electrode is located at the bottom of the container and serves as the reference electrode. The other electrode changes depending on the level of the liquid. When the liquid level rises, the liquid will come into contact with the changing electrode, forming a liquid-electrode-reference electrode capacitance structure, and the capacitance value increases. On the contrary, when the liquid level decreases, the capacitance value between the liquid and the changing electrode decreases.

3.Technical advantages

This series of Capacitive Oil Level Sensors are metrology-grade measuring instruments with high resolution and measurement accuracy.

Capacitive Oil Level Sensor requires no manual intervention, is automatically calibrated, has no temperature drift, and is not affected by changes in the medium.

The same transmitter can correctly output accurate liquid level and height signals regardless of whether the medium being measured is water, gasoline or diesel, regardless of temperature changes. It completely solves the problem of difficult measurement of ethanol gasoline, methanol fuel and other media. It also solves the problem of measurement errors caused by different oil labels and huge differences in temperature in different regions.

The capacitive oil level sensor does not have any elastic parts or movable parts, and is impact-resistant and easy to install. It can be installed in various occasions to accurately measure the oil level of gasoline, diesel, hydraulic oil and other weakly corrosive liquids.